When it comes to vehicle maintenance, having the right tools can make all the difference. One of the most essential tools in any car or truck owner’s inventory is the car jack. Jacks are used to lift vehicles, enabling repairs, maintenance, and tire changes. However, using jacks improperly can be dangerous, so it’s crucial to understand the different types of jacks available on the market, and how to use them correctly. In this guide, we’ll explore various types of car and truck jacks and provide valuable insights into their safe and proper usage. Read on!

Types of Car and Truck Jacks

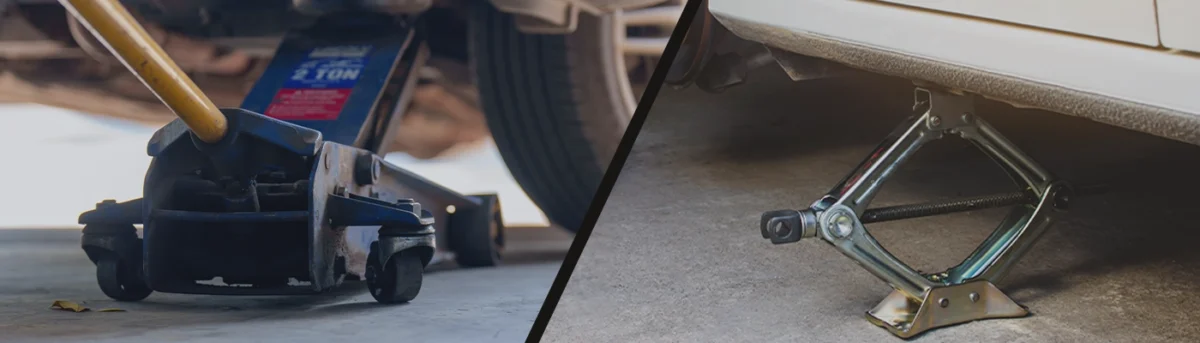

1. Hydraulic Floor Service Jacks:

These jacks are commonly found in garages and workshops. They utilize hydraulic pressure following a principle called Pascal’s law to lift all types of vehicles. Hydraulic floor jacks are robust, durable, efficient, and capable of lifting heavy vehicles with ease.

2. Scorpion Floor Jack:

Stan Design’s patented Scorpion Floor Jacks are designed to make short work of heavy lifting. From small cars to trucks, and EVs to armored cars, you can lift anything in seconds with the Scorpion Floor Jack! Built from premium-grade materials, these revolutionary new jacks can be operated with the push of a button. They also have a small footprint and a low collapsed profile to maximize workshop space. A three-stage locking system ensures extra safety in the workshop environment. With a lifting capacity of up to 14 tons, Scorpion Floor Jacks help increase revenue by reducing session time and increasing vehicle inflow for workshops.

3. Pit Jacks:

Pit jacks, as the name suggests, are designed to operate in service pits for easy access to the underside of vehicles. These jacks are robust and can lift vehicles of all dimensions and weights using hydraulics. A revolutionary new iteration of the conventional pit jack is Stan Design’s Scorpion Pit Jack. Built from premium-grade materials, the Scorpion Pit Jack utilizes dual hydraulic cylinders assisted by pneumatic pressure to lift trucks and other vehicles. These pit jacks are also designed to fit into any vehicle servicing pit and come fitted with roller-bearing wheels to allow easy maneuvering. A three-stage locking mechanism ensures that the Scrpion Pit Jack is safe to use even when lifting armored cars!

4. Rolling Bridge Jacks:

A rolling bridge jack is a valuable tool in car repair workshops. It works with big lifts to elevate different car parts. The rolling bridge jack moves smoothly on the lift’s tracks, making components like wheels, brakes, and other essential parts easily accessible.

Stan Jacks is a revolutionary new take on the standard rolling bridge jack. Built to last, Stan Jacks utilizes heavy-duty hydraulics and pneumatics with advanced safety features and intuitive control mechanisms to make short work of heavy lifting.

5. Scissor Jacks:

Scissor jacks are often provided with cars as part of the standard toolbox by manufacturers. They are compact and lightweight, making them convenient for emergency situations or minor repairs. However, they require more effort and time to operate compared to hydraulic jacks. But it’s always advisable to carry a scissor jack whenever possible because you never know when you’ll need a tire change!

6. Bottle Jacks:

Bottle jacks are robust and capable of lifting heavy loads. They have a cylindrical bottle-like shape and work on the same principle as hydraulic floor jacks. Bottle jacks are commonly used for lifting trucks and larger vehicles. Their small footprint makes them easy to carry around. However, one complaint about this iteration of the popular hydraulic jack is that it doesn’t lift high enough.

7. Hi-Lift Jacks:

Also known as farm jacks or off-road jacks, hi-lift jacks are versatile tools frequently used by off-road enthusiasts. They can be used not only for lifting vehicles but also for winching and clamping. So, if you are going off-roading on rugged terrain, consider carrying one with you to free your vehicle from those really deep ditches.

8. Pneumatic Jacks:

Pneumatic jacks use compressed air to lift vehicles. They are often used in professional fast-paced automotive environments where efficiency is crucial. Pneumatic jacks provide rapid lifting and lowering capabilities but tend to be on the expensive side. Besides, you also need a reliable supply of compressed air to operate pneumatic jacks.

9. Electric Car Jacks:

Essentially a scissor jack with a strapped-on motor, the electric jack is a modern innovation that combines the user-friendliness of a conventional scissor jack with the instant torque provided by an electric motor to lift cars and light vehicles. These jacks are powered by your vehicle’s electrical system and can lift the vehicle at the push of a button. Electric jacks are especially handy for those with limited physical strength. But it is advisable not to try them on heavy vehicles like trucks.

How to use jacks properly:

- Choose the right jack: Select a jack that’s appropriate for your vehicle’s weight and size. Check your vehicle’s manual for weight specifications and recommendations.

- Safety first: Always park your vehicle on a level surface before using a jack. Engage the parking brake and place wheel chocks on the opposite wheels to prevent rolling.

- Find a suitable lifting point: Consult your vehicle’s manual to identify the proper lifting points. These points are usually located along the vehicle’s frame. Avoid lifting under the body, suspension, or any other non-reinforced areas.

- Prepare the jack: When using a hydraulic jack, ensure that the release valve is closed before pumping the handle. With scissor jacks, insert the handle and rotate it as needed to extend the arms.

- Lift gradually: Operate the jack gradually and smoothly. Avoid sudden movements that could destabilize the vehicle. For hydraulic jacks, pump the handle with consistent pressure.

- Use jack stands: Never rely solely on a jack to support your vehicle while working underneath. Once the vehicle is lifted, place jack stands under the proper support points for added security.

- Lower Carefully: When you’re done working, lower the vehicle gently. Remove the jack stands first, and then release the hydraulic pressure or turn the handle slowly for scissor jacks.

- Maintenance: Regularly inspect your jacks for signs of wear and tear. Check hydraulic jacks for leaks and ensure proper functionality. Lubricate moving parts as recommended by the manufacturer.

Car jacks are indispensable tools for vehicle owners. If you are a vehicle or workshop owner, always use jacks made by trusted manufacturers like Stan Design. Only they have the know-how to build products that are efficient, safe, and long-lasting.