What is Scorpion Fast Lube Equipment?

We at Stan Design are a leading producer of jack equipment and fast lube systems in the Canadian market. With jacks of different operating mechanisms like mechanical or electrical, air powered, hydraulic or perhaps a hybrid system, we had an enormous number of options in front of us.

For the best fast lube system benefits, we opted for two variants- air powered and heavy-duty hydraulics. Essentially, our Scorpion fast lube equipment is powered by air bags or hydraulics for smooth, safe and efficient automotive repairs and maintenance like loading, lifting, suspending and lowering heavy vehicles.

Apart from that, it also helps you to offer tire rotation and tire service to your customers. This helps you generate more revenue and profit for your business, which, as per some industry statistics, can be at least $24,000 per year. All this for an affordable investment of an entry point as low as $4000, eliminating the need for hand pumping.

Scorpion fast lube equipment jacks are made with high-quality materials which add to their durability and reliability. Their cutting-edge design of innovative features makes them easy to use, safe to operate, and fit your pit.

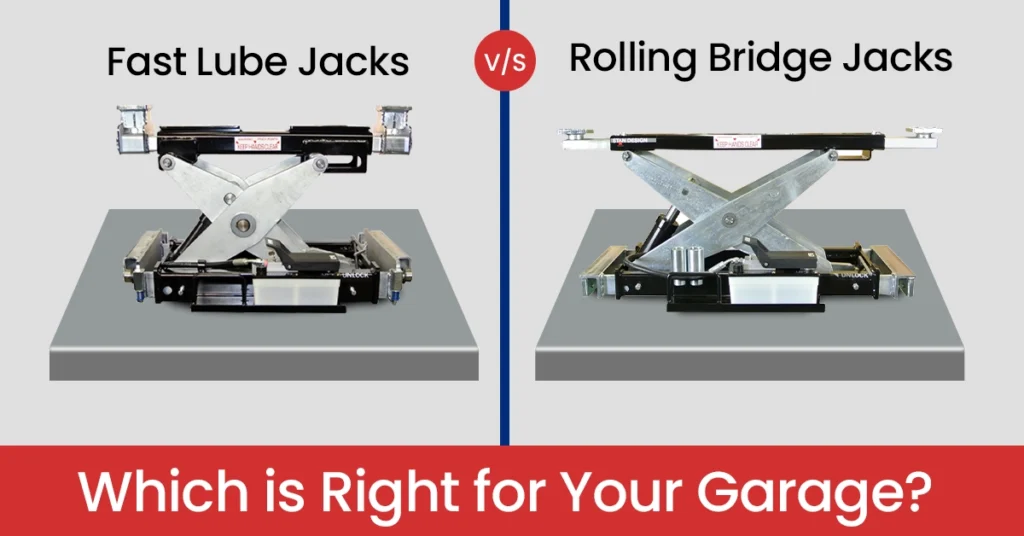

Scorpion Fast Lube System Benefits

Scorpion fast lube system benefits are manifold. Below we will discuss the features of this specialized rolling pit jack, so sit tight and read on.

- Smooth Lifting– The Stan Design Inc. Scorpion fast lube equipment is a rolling pit jack that comes in dual operating mechanisms- air bags and hydraulic cylinders. Because of this choice in options, you can either buy a product that helps you lift heavy-duty vehicles by getting inflated through air power or which works on the principle of fluid mechanics inherent in hydraulic systems. Either way, you get a smoother lifting result than ordinary jacks available in the market. And it does not end there. The lifting and lowering time is also shortened to a quick few seconds with the convenience of a button push, instead of rigorous manual hand pumping.

- Full Control Always– Which brings us to the next benefit. The Stan Design Inc. Scorpion fast lube equipment comes with a detachable remote-controlled pendant with two buttons- one to lift and one to lower. This seeming simple feature is an advanced technological and critical security advancement adopted by us to combat the probability of accidents and mishaps typical of fast lube system operators. Besides being the cutting-edge technological innovation that a detachable remote-controlled pendant is with regards to eliminating the manual labour as well as time consumption characteristic of traditional lifting jacks, its security accommodation is brilliant. The separate buttons with different and specific functionality give you full control over the jack at all times.

- Easy Maneuvering– The Scorpion fast lube equipment is armed with special roller bearing wheels. This means that their structure includes four full floating casters that allow for easy rolling and maneuvering. The wheels are made of special roller bearings that reduce friction and wear. Generally, rolling pit jack wheels bear the brunt of the heavy lifting they are involved in, and understandably so. That is why they are perhaps the most prone to malfunction. Such a mishap at a wrong time can disrupt not only the functionality of the jack but also the efficiency of the commercial garage employing it. That is why we came up with these special roller bearings so you could sit back and relax as a garage owner without worrying about the productivity or reputation of your establishment.

- Simple to Position– Fast lube equipment is loaded with low and high adapters that can be stacked together to fit different vehicle sizes and shapes. The adapters are stored on the jack for convenience. This, coupled with a pull handle, makes it simple to position the jack under the vehicle. The handle can also be extended for rear axles. The low-profile of our fast lube rolling pit jacks also add to the effectiveness of this desired outcome to be easily and accurately positioned under the chassis or undercarriage of the vehicle intended to be lifted for maintenance.

- Corrosion Proof– Scorpion fast lube equipment is finished with a high gloss powder coat paint that protects them from rust. They also have zinc plated components and accessories that resist oxidation and deterioration. These dual capabilities of their finishing touches enhance their durability as well as appearance and give them a sleek and professional look. Although it is generally advisable to clean your jacks neatly after every use and store them in dry and clean environments, out of direct sun exposure, their zinc plating and high gloss powder coat paint can protect them from short-term neglect.

Safety Features in Scorpion Products

Stan Design’s Scorpion fast lube equipment is a part of its Scorpion line of jacks. These jacks, apart from the beneficial features mentioned above, are best known for their safety features. A hallmark of safety features in Scorpion products are the best and most reliable in the industry. Besides, every innovative feature of the Scorpion fast lube equipment doubles as a security enhancement.

The built-in three-stage locking system which is integrated with the loading and lifting mechanism of all jacks are the product of cutting-edge technology meeting usable and functional design. This not only automatically engages at different height levels, but also eliminates the need for additional jack stands or chocks. Its durable components and sturdy build material also add to its reliability and safety of operation.

Boasting incredible features like heavy-duty hydraulics, extended lifting height, low collapsed height, and a narrow top beam of 34.5”, this precision-crafted fast lube pit jack range is built to last and includes the following models-

- Capacity- 6,000 lb./3 Ton

- Capacity- 7,500 lb./3.75 Ton

- Capacity- 7,000 lb./3.5 Ton

- Capacity- 9,000 lb./4.5 Ton