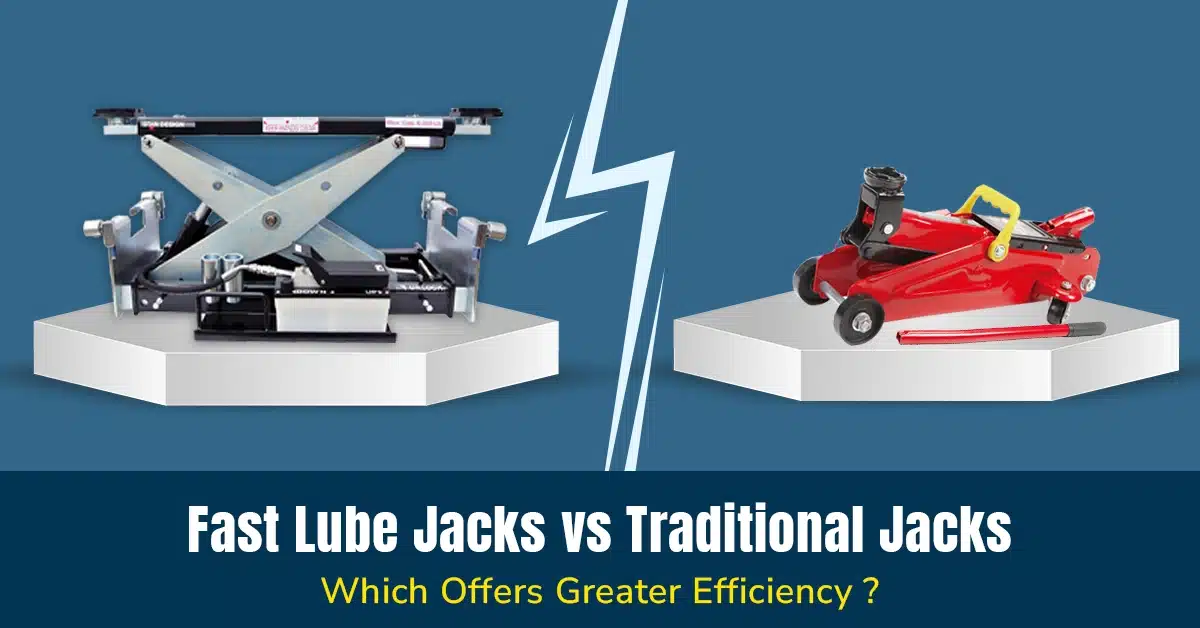

An easy-to-use and high-quality jack is essential for vehicle maintenance, whether you are a DIY enthusiast, a motorhead, or a professional auto technician. The 2 most common versions of jacks available currently are fast lube jacks and the older, traditional ones. Fast lube jacks have gained greater currency over the past few years and are a staple for mechanics since these can help you save at least $24,000 every year on tire rotation services!

But which ones of these are the best and how do they match up against each other? If you have read this far, chances are you already have a good idea about heavy duty jacks for trucks and related sets of equipment. Still, let us begin with a brief introduction of the 2 types.

Decoding Fast Lube Jacks

Fast lube jacks, better known as quick jacks, are designed primarily for both speed and convenience. Quick jacks are very common in quick vehicle service stations where time really is of the essence. Fast lubes are hydraulic jacks that can lift a vehicle quickly and with minimal effort. The design template typically includes a lever system that allows for easy operation.

Benefits of Fast Lube Jacks:

- The element of speed: Fast lube jacks are incredibly quick in their operation. They can lift a minivan or a large SUV in seconds, making them ideal for any environment where time is critical.

- A lot more user-friendly: They are designed to be a lot more user-friendly. The hydraulics work better in these sets.

- More portable: Most – if not all – fast jacks are super-portable, making them easy to move around and to use in several different locations and conditions.

- Safer operations: All modern fast lube jacks come with built-in safety features expressly designed to prevent accidents.

Drawbacks of Fast Lube Jacks:

- Can be expensive: Did you see the list of benefits these heavy duty pit jacks offer? On the downside, it makes them more expensive than the standard versions.

- Require more maintenance: While this may or may not sound like a drawback, given that tools of all sorts require care, these jacks require more maintenance to ensure seamless functionality.

Traditional Jacks

As the name suggests, these jacks have been around for a long time and are almost as old as vehicles themselves. They come in various forms, such as bottle jacks, scissor jacks, and floor jacks. These jacks rely solely on their mechanical advantage to lift a vehicle.

Benefits of Traditional Jacks:

- The affordability factor: Traditional jacks are almost always less expensive than fast lube jacks.

- More durable: Traditional jacks are built to last and are capable of withstanding heavy & even neglectful use over longer periods.

- Extremely simple to use: Because they have fewer moving parts, maintaining and using them is much easier. In comparison, the fast jack is a Swiss watch!

- More versatile: Traditional jacks can be used for a variety of applications beyond just lifting vehicles.

Drawbacks of Traditional Jacks:

- Time-consuming: Lifting a vehicle with a standard jack requires extra time and effort.

- More physical effort needed: Traditional jacks require a lot of physical effort to operate, making it off-putting to many users.

- Portability problems: Some traditional jacks, floor jacks being a good example, are bulky and not designed to be carried around. .

Comparing Efficiency Levels

Let’s now compare their efficiency based on a few key factors, namely speed, ease of use, the price factor, and versatility.

Speed:

Based on swiftness of operations, fast lube jacks are the clear winners. They can lift a vehicle in seconds, something traditional jacks can take several minutes to do, especially if you’re using a scissor jack or even a bottle jack. If you run a service station, for example, and need to handle multiple vehicles simultaneously or in short spans, fast lube jacks are irreplaceable.

Ease of Use:

Quick jacks are designed to be easily accessed. The hydraulic assistance combined with lever systems makes lifting heavy vehicles a breezy affair. Traditional jacks are more cumbersome and certainly more physically demanding. If more efficient use is what you need, go for fast lube jacks.

The price factor:

Traditional jacks are a lot more affordable than fast lube jacks. If budgetary constraints are a big concern, traditional jacks might well be the superior option. Don’t forget the long-term benefits and potential time savings offered by fast lubes, however.

Versatility

Traditional jacks are more versatile in their applications. Do you also need to sometimes lift heavy machinery or require supporting machinery during extensive repairs of, say, buildings? If so, opt for the older variants since fast lube jacks are designed specifically for lifting vehicles.

A few other considerations

- How frequently will you use it: If lifting your vehicle is something you do very often, opt for the speed and ease of use of fast lube jacks.

- Types of vehicles you use: This is an issue that only automotive insiders are aware of. The type and weight of vehicles you’re working with should always influence your choice. Fast lube jacks are especially designed for passenger cars and light trucks, while traditional jacks can handle a wider range of weights and are also used as heavy duty jacks for trucks.

For example, if you’re working on your trusty pickup or a van, it would make more sense to use a traditional jack. Likewise, trust a fast jack to lift a medium-to-large passenger car or a hatchback, or a coupe with ease

- Budget: Assess your budget and allow for the long-term benefits of the 2 types. Yes, fast lube jacks do have a higher upfront cost. Then again, their efficiency can lead to cost savings in a high-volume (read professional) work environment.

And the winner is…

As it stands, fast lube jacks and the grand old traditional jacks have their place in vehicular maintenance. Fast jacks are a lot more efficient in terms of speed and ease of use, traditional jacks are a lot more affordable and exceedingly versatile, and are suitable for a range of applications, as well as the occasional, one-time use.

Ultimately, the choice boils down to your specific needs, the amount of money you can invest, and your work environment. If you’re a professional and are intent on scaling up your repairs and fitments business, you need both speed and convenience in a time-bound setting, and you require fast lube jacks!

But if you want versatility and lower prices over everything else, traditional jacks are certainly a better fit.

The top 3 Stan Design pit jacks available right now:

Pit Jacks J7500HFL

- Capacity- 75,000 lbs.

- Narrow 34.5” Top Beam

- Heavy Duty Hydraulics

Pit Jacks J7000LFL

- Capacity- 7,000 lbs.

- Narrow 34.5” Top Beam

- Heavy Duty Hydraulics

Pit Jacks J9000HFL

- Capacity- 9,000 lbs.

- Narrow 34.5” Top Beam

- Heavy Duty Hydraulics

Learn More about: Stan Jack accessories for Sale!