The All Essential Automotive Tools

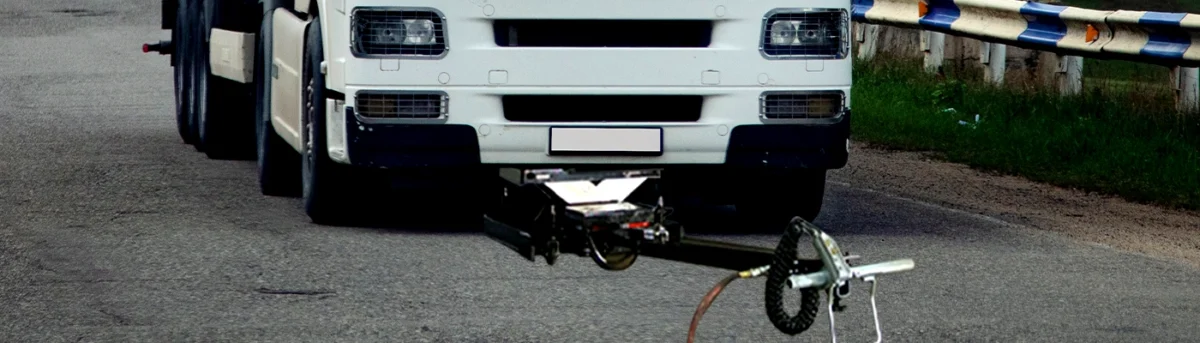

A heavy-duty floor jack is a must-have tool for any workshop owner or DIY car enthusiast. Maintenance and repairing activities like changing a tire, fixing the wheel assembly, or lubrication – basically anything that has to do with the undercarriage of a vehicle – require it to be lifted high enough for technicians to reach the undercarriage safely. Hence, you need heavy-duty floor jacks to lift heavy trucks, semis, cars, and every other type of vehicle effortlessly and safely.

If you are new to using truck jacks or floor jacks, this blog will help you understand the basics of lifting a heavy vehicle safely for repairs. Read on!

Tools and Accessories You’ll Need

Before you start, keep the following tools and accessories handy:

- Heavy-duty floor jack: Ensure it has the capacity to lift your truck’s weight.

- Jack stands: These provide critical support once the truck is lifted.

- Wheel chocks: To prevent the truck from rolling while lifted.

- Lug wrench: To loosen the lug nuts if you’re working on the wheels.

- Safety gloves and goggles: For personal protection.

Step-by-Step Guide

- Choose the Right Location: Park your truck on a level surface and engage the parking brake.

Make sure the area is well-lit and free from any obstacles. - Prepare the Vehicle: If you’re lifting the truck to work on the wheels, use the lug wrench to slightly loosen the lug nuts on the wheels you plan to remove. Remember, do not remove them completely. This will make it easier to remove the wheel later.

- Place Wheel Chocks: Position wheel chocks against the wheels touching the ground. This will prevent the truck from rolling while it’s lifted.

- Locate Jacking Points: Consult your truck’s owner’s manual to find the recommended jacking points. These are usually located on the undersurface of the vehicle, near the wheels. They are reinforced sections of the frame designed for lifting. Remember, using a heavy-duty floor jack on any other section of the vehicle for lifting can cause serious damage to the chassis, leading to unnecessary expenses.

- Position the Heavy-Duty Floor Jack: Place your truck jack or heavy-duty floor jack under the selected jacking point. Ensure the jack’s saddle is correctly aligned with the jacking point to prevent chassis damage.

- Pump the Jack: Slowly pump the handle of the floor jack until the truck starts to lift. Keep an eye on the vehicle as it rises and stop when you’ve reached the desired height. Be cautious not to exceed the jack’s weight capacity.

- Insert Jack Stands: Once the truck is raised, immediately position jack stands under the recommended jacking points, making sure they’re secure and the vehicle is resting on them.

- Test Stability: Gently shake the truck to ensure it’s stable on the jack stands. If it wobbles or doesn’t feel secure, lower it back onto the floor jack and reposition the jack stands.

- Perform Repairs or Maintenance: Now that the truck is securely elevated, you can perform the necessary maintenance or repairs.

- Lower the Truck: When you’re finished working, carefully remove the jack stands and slowly lower the truck using the floor jack.

Conclusion Using a heavy-duty floor jack to lift a truck is a skill that can come in handy for various maintenance and repair tasks. Safety is paramount, so always follow the steps described above and take precautions such as using wheel chocks and jack stands. And always remember to buy heavy-duty floor jacks from reputed manufacturers like Stan Design to ensure safety, efficiency, and durability.