Vehicle owners nationwide depend on full-service workshops for things like oil change, and tire rotation. Without these routine maintenance jobs, cars and trucks can develop serious functional issues including engine seizure and misaligned tires.

If you are in the workshop business, there are a couple of things you must do to ensure a more streamlined fast lube process. Here they are:

- Step 1: Greet your customers and check them into your system.

- Step 2: Perform light checks.

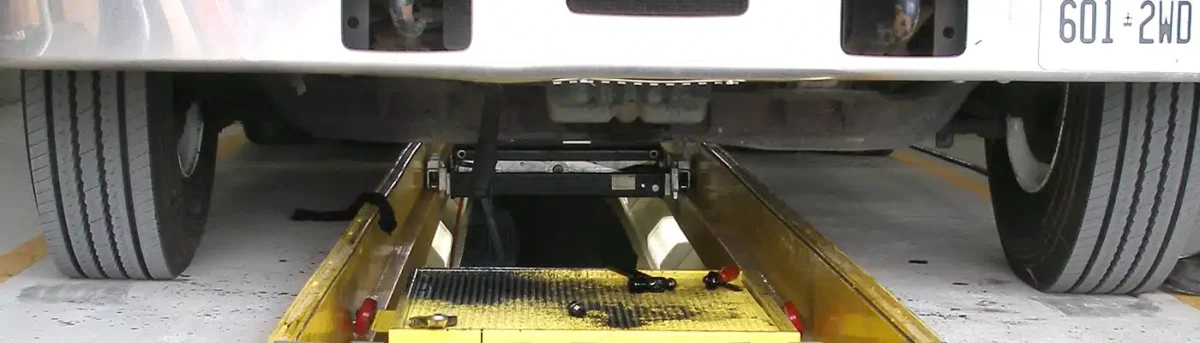

- Step 3: Check for wheel alignment issues as soon as the customer pulls into your bay.

- Step 4: Review service history, recommendations, and benefits with your customer.

- Step 5: Perform a quick oil change and undercarriage inspection. Suggest repair jobs if you spot old, unresolved maintenance issues.

- Step 6: Perform a quick tire rotation.

- Step 7: Guide the customer out of the bay after completing the checkout process.

But none of these can be implemented unless you have quick and reliable lube equipment in your workshop. And this brings us to our topic of discussion – how to acquire fast lube jacks in Canada.

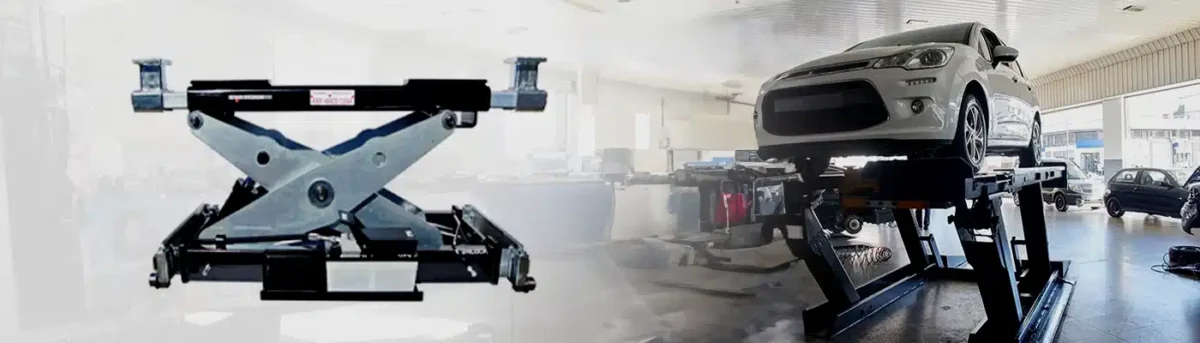

A Quick Word on Fast Lube Jacks

Did you know that by offering tire rotation service to your customers, you can earn as much as $24,000 a year? That’s a handsome amount for a small business! The best fast lube jacks in Canada share the same set of attributes.

- They are affordable.

- The best fast lube jacks offer hydraulic and airbag models for fast and smooth lifting. It’s up to you to decide which one fits best in your workshop.

- Built-in safety locking mechanisms make the lifting process safe for the operator and car owner.

- The best fast lube jacks have intuitive controls for easy operation.

- Fast lube jacks like the J7000L Low Boy from Stan Design feature stackable adapters to suit all vehicle types.

- The individual components of the quick lube equipment are built to last long in the demanding environment of a workshop.

How to acquire quick lube equipment in Canada?

Canada is home to some of the best car and truck jack manufacturers in the world. Thanks to them, you can buy world-class pit jacks, floor jacks, and quick lube equipment online. All you need to do is browse the internet for fast lube jacks and choose one that’s affordable and well-reviewed by customers. High-quality fast lube jacks are competitively priced, so you don’t have to invest a large sum of money to get one for your workshop.

Top 5 fast lube jacks in Canada

1. The J7000L Low Boy Rolling Jack from Stan Design

Stan Design has been in the forefront of manufacturing some of the best quality truck jacks in the world. The J7000L Low Boy fast lube jack lives up to expectations with some incredible features.

Pros:

- Class-leading 7000 lbs. lift capacity. Lift capacity doubles with a 2-jack setup.

- Fits any service pit.

- Works on all vehicle types thanks to a set of adapters.

- Robust airbag-operated lift mechanism lifts heavy trucks in no time.

- Durable components require very little maintenance.

2. The RR70G Rolling Bridge Jack from Forward Lift

Forward Lift has been in the business of manufacturing high-quality 2-post and 4-post lifts, bridge jacks, and motorcycle lifts long enough to become a force to reckon with. The RR70G is a top-notch quick lube equipment with features that make it a fan favorite.

Pros:

- Class-leading 7,000 lbs. lift capacity.

- Works seamlessly with 4-post lifts.

- Robust components and durable hydraulic and pneumatic systems last long enough to return great value for money.

3. The Atlas RJ-35 Sliding Hydraulic Center Jack from Atlas Automotive Equipment

Here’s another high-quality quick lube equipment from a reputable manufacturer – Atlas Automotive Equipment. To say that the RJ-35 fast lube jack is good would be an understatement.

Pros:

- 3,500 lbs. lift capacity suits most small and mid-sized vehicles.

- A robust scissor mechanism makes lifting operation smooth and efficient.

- A collapsed width of 29 ½” fits any lift.

- Lifts vehicles up to 18”.

- Safety locks ensure secured lifting.

4. Stan Jack J9000H Bridge Jack by Stand Design

It’s impossible to ignore Stan Design when it comes to discussing quick lube equipment, isn’t it? Their inventory always teems with class-leading floor jacks and fast lube jacks that never fail to set new benchmarks in quality.

While the J9000H has been around for some time, it never stops amazing users with its robustness and user-friendly features.

Pros:

- Lifts up to 9000 lbs.

- Heavy-duty hydraulic and pneumatic lifting apparatus matches up to vehicles of any size or dimension.

- A low collapsed height and extended lifting height of 11” make the J9000H the best fit for 2 and 4-post car lifts nationwide.

- We don’t have to tell you that Stan Jacks are built to last, do we?

5. BendPak RJ45W Rolling Bridge Jack from BendPak

The name BendPak spells quality. With a long history in manufacturing quick lube equipment, BendPak has been at the forefront of manufacturing premium vehicle lifting solutions at an affordable price point. The RJ45W fast lube jack is a fan-favorite product from their stable.

Pros:

- Lift capacity of 2041 kg/4500 lbs.

- Minimum drive-over height of just 114mm/4.5”.

- Dual hydraulic arms extend up to 1447mm/56”.

- The RJ45W comes equipped with easy-roll wheels that fit into any channel on standard 4-post lifts.

- Special rubber contact pads to ensure no damage happens to the subframe during the lifting process.

- Durable components last for decades making the product great value for money.

- Stackable adapters make sure that the RJ45W works on any vehicle you throw at it.

Summing it up

No matter which quick lube equipment you buy for your workshop, ensure that it is made from high-grade steel and carries an anti-rust coat for increased lifespan. And never compromise on safety features.