Introduction of Pit Covers

Automotive workshops together with commercial garages function as active environments where mechanics dedicate their time to maintain vehicle functionality. Service and inspection pits serve as essential tools to inspect vehicle undersides, but they become hazardous when they remain without protection. Open pits are the most common workplace hazard that leads to industrial injuries among automotive workers since they cause sprains fractures and occasionally fatal accidents. Pits without protective covers accumulate oil grease and debris which leads to unsafe conditions that might be toxic.

Safety solutions depend on pit covers as the essential answer to these problems. The Canadian company provides premium pit covers that deliver safety along with durability and operational functionality. These custom made pit covers accommodate different sizes and budgets which makes them suitable for workshops in North America. This blog post examines pit covers through their features and benefits and special characteristics and shows how these components transform your workshop into a safer space with improved efficiency.

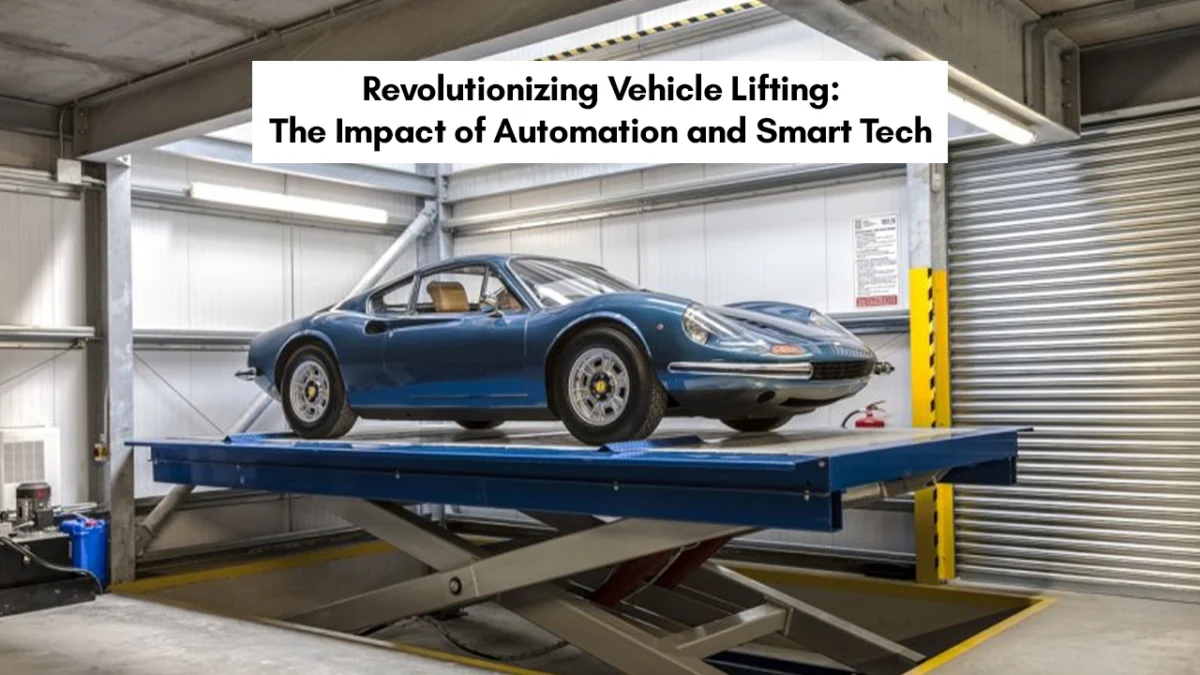

Additionally, the solution to these problems requires pit covers as essential safety equipment. The PLC1000 model stands out because it was created to meet practical and safety requirements. The PLC1000 is a pit cover system heavy-duty design that perfectly covers standard service pits while providing easy-to-use covering systems. The model includes pneumatic release and locking features which provide complete user safety throughout pit access procedures. The combination of roller-bearing wheels and telescoping arms enables easy movement throughout restricted shop areas. The cover operates with ease for mechanics who work without discomfort and shop owners benefit from its durable construction and decreased liability risks. The PLC1000 manufactured in Canada meets the highest industry standards while delivering functional safety and cost-effective performance for commercial vehicle maintenance in busy garages

Key Features of Pit Covers

The pit covers designed by combine precise engineering with careful construction to provide various features suitable for contemporary automotive workshops. These characteristics make the product stand out:

- Custom Fit: The system is designed to match your specific pit size for a complete seal with no gaps.

- Durability: The powder coat paint resists corrosion and the zinc-plated components provide durability.

- Safety Mechanisms: Three-stage locking system with pneumatic release for secure operation.

- Ease of Use: A pull handle and roller bearing wheels enable easy movement between opening and closing operations.

- Lifting Capability: Likely supports heavy-duty lifting, ideal for trucks and buses.

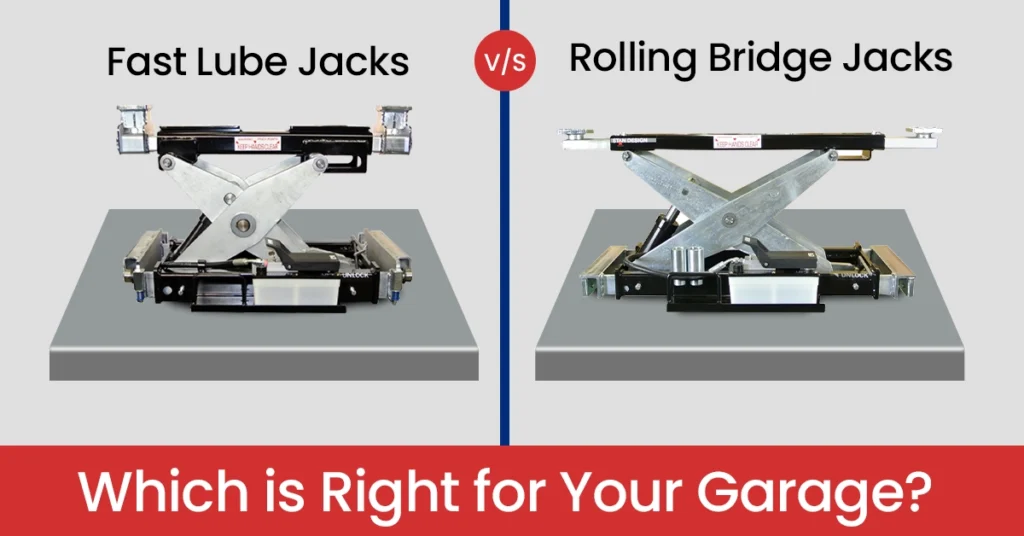

- Versatility: Telescoping arms allow users to pick up items from flexible points which work with different vehicle types.

- Canadian Quality: Canadian manufacturing facilities produce these products under demanding quality control measures.

The combination of practical features and safety measures in these pit covers makes them suitable for daily workshop usage. The lifting capability stands out as a key differentiator for Stan Design because it enables workshops to complete wheel alignment and tire rotation tasks directly from the pit.

Benefits of Using Pit Covers

Pit Covers provides your workshop with various advantages that both improve safety and boost operational efficiency.

Open pit coverage provides enhanced protection for both employees and customers by decreasing their fall risk. The locking system maintains the cover position and reduces workplace hazards.

- Cleaner Environment: By preventing debris and fluids from collecting in the pit, the covers maintain a hygienic workspace, reducing slip hazards.

- Increased Efficiency: The built-in lifting system allows workshops to operate on heavy vehicles without additional tools which accelerates their service operations.

- Cost Savings: Durable materials and low maintenance needs mean long-term savings. Insurance and liability expenses decrease when accidents become fewer.

- High-quality: Pit Covers provide organizations with regulatory compliance while protecting employees from workplace safety violations which leads to cost reduction through avoidance of penalties and operational conformity.

Why Stan Design’s Pit Cover Stands Out?

- Traditional Covers: Wooden planks can warp or break and basic metal covers may not fit properly. The custom-fit design of Stan Design provides stability while maintaining safety.

- Competitors: Stan Design offers customized pit covers that match your specific needs better than generic solutions found elsewhere. The lifting feature provides a distinctive benefit which is not standard in similar products.

- Quality Assurance: As a Canadian manufacturer, Stan Design adheres to rigorous standards, delivering reliable, high quality products.

Workshops select Stan Design as their preferred provider because of its dependable safety solutions..

Customers Feedback who used Pit Cover Stan Design –

John T., Workshop Owner: “These pit covers are a game-changer. These pit covers enable smooth handling of heavy trucks while delivering exceptional safety performance through their top-quality locking mechanism.

Emily R., Garage Manager: “The features are fantastic, especially the pneumatic release. I highly recommend these covers.”

The testimonials demonstrate the functional advantages and customer contentment that users receive when selecting Stan Design products.

Workshops that want to boost safety and operational efficiency should pit covers as their fundamental investment. The custom-fit pit covers provide durable construction and advanced safety features with potential lifting capabilities to address open pit challenges while delivering operational versatility. These Canadian-made covers meet high Canadian quality standards while establishing themselves as the preferred choice for North American workshops.

The time has arrived for you to establish a safer workplace that increases productivity. The Stan Design website enables you to discover more about their pit covers while allowing you to obtain customized pricing information. This advanced solution provides both operational efficiency and workplace safety protection for your team through its implementation.

Open pits create a danger to your workshop operations. The team at Stan Design provides custom quotes for pit covers that you can explore through their website. You can begin by clicking here or contacting a representative through a phone call.