Every day, hundreds of thousands of trucks navigate the freeways of North America, carrying essential commodities to the farthest reaches of Canada and the USA. The continent’s enormous network of vehicle servicing workshops functions as the backbone of the trucking industry. And if there’s one tool the workshops can’t do without, it’s the heavy-duty truck jack.

What’s so special about truck jacks?

- Truck jacks facilitate undercarriage repair. The undercarriage takes a lot of beating as vehicles crisscross all kinds of terrain. Without heavy-duty truck jacks, it would be impossible to lift vehicles high enough for the inspection and maintenance of everything from the wheel assembly to the exhaust system.

- Truck jacks are robust tools and last years under rigorous use. High-quality truck jacks return great value for money, making them prized possessions among workshop owners.

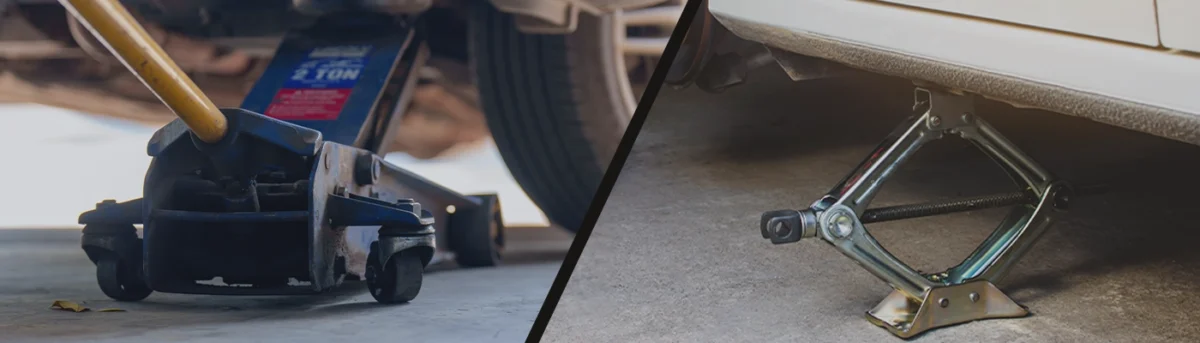

When it comes to buying truck jacks, there are a lot of options to choose from. You have hydraulic floor jacks, bottle jacks, bridge jacks, and our topic of discussion for today – pit jacks.

What’s so special about pit jacks?

Time is money, more so in the world of truck and bus maintenance. So, workshops servicing trucks, buses, and other heavy vehicles need a tool that is quick, smooth, efficient, and safe, and what’s better than a pit jack for the job?

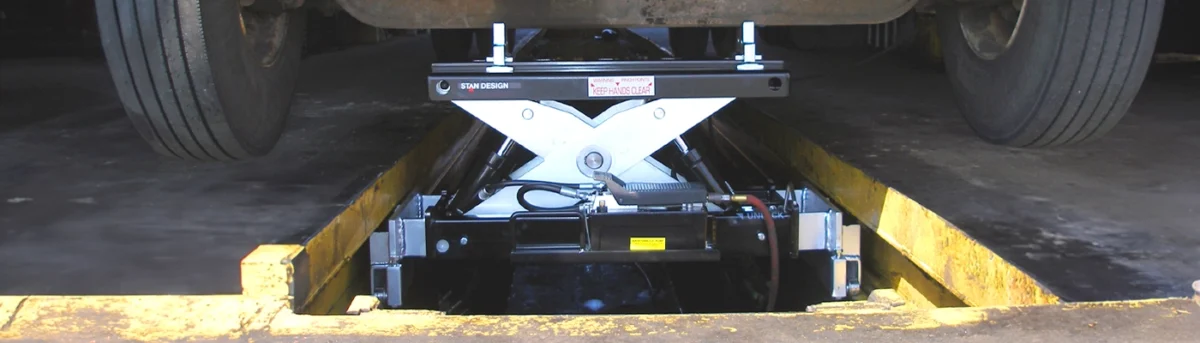

Workshops with dedicated inspection pits use pit jacks to lift all kinds of vehicles for undercarriage repair. Think of them as scissor jacks on steroids! At the heart of every pit jack is a hydraulic system aided by a pneumatic (compressed air) lifting apparatus. Dual lifting arms when actuated lift cars and trucks weighing tons high enough for easy access to the subframe.

Here’s why pit jacks stand out as super-efficient tools in the vehicle lifting solutions industry:

- They are robust tools, easy to maintain, and last for years on end.

- Pit jacks are built to lift loaded trucks. So, they have high weight capacities to tackle any kind of vehicle.

- The lifting operation in pit jacks is precise and accurate, aided by multi-stage locking mechanisms for added safety.

- They are safe and easy to operate, eliminating the need for specialized training.

All this amounts to increased efficiency, reduced downtime, and more profits for a workshop business. No wonder, workshop owners love pit jacks!

The Scorpion Pit Jack – your workshop’s biggest ally!

What the Scorpion Pit Jack does is take all the characteristics of the standard pit jack and make them better.

Let’s explore why this winning product from our stable can be a complete game-changer for your workshop business.

1. Unrivaled Lifting Power

Pick any product from our line of pit jacks, and you’ll see a robust hydraulic lifting apparatus in its core. The hydraulic apparatus is aided by a compressed air system for additional power, resulting in some of the meanest tools money can buy.

Take for instance the Scorpion PJ35 Pit Jack. It can lift vehicles as heavy as 35,000 lbs. effortlessly in no time. Whether it’s for routine maintenance or complex repair jobs, the Scorpion Pit Jacks make light work of the heaviest loads. Let’s just say, we are here to raise the bar when it comes to the raw lifting power of pit jacks.

2. Smart Design and Durable Build

With the help of precision engineering and years of experience in product development, we have come up with a blueprint for producing floor jacks, bridge jacks, and pit jacks that trump competition with their smart design and unmatched durability.

Our battle-ready Scorpion Pit Jacks are designed to survive and triumph in harsh conditions and under rigorous use. Hardened steel frames and rams, zinc-plated components, anti-rust coating, and precision-engineered hydraulic and pneumatic systems all contribute to the build quality of the Scorpion Pit Jacks. Our Scorpions certainly have stings in their tails!

3. Precision is the Name of the Game!

What’s a pit jack without precision lifting abilities? The Scorpion Pit Jacks excel in this department with hydraulic systems engineered for controlled movements. Technicians can elevate vehicles with pinpoint accuracy and rely on the built-in safety mechanisms to keep them safe.

4. Adaptability for Varied Fleets

No two vehicles are the same. We design our products keeping in mind all the different car and truck types currently running on the road. The Scorpion Pit Jacks come with stackable adapters to lift all kinds of cars and trucks across the axle.

A compact profile expandable up to as much as 46” ensures that these heavy duty truck jacks fit any inspection pit in the country.

5. Unmatched Safety Features

Safety is non-negotiable, and the Scorpion Pit Jacks prioritize it with advanced safety features. Automatic locking mechanisms engage when the desired height is reached, securing the lifted truck in place.

Our commitment to safety provides technicians with peace of mind as they perform critical tasks beneath the elevated vehicle.

6. Efficiency Redefined

Time is money in the world of logistics. The Scorpion Pit Jacks are engineered to be quick and efficient. Swift lifting enabled by intuitive controls reduces downtime drastically for trucks, increasing the operational efficiency of workshops.

Endnote

When you buy a Scorpion Pit Jack, you carry home a tool that’s been designed by engineers who know and cherish their craft. Our lifting solutions aren’t just tools for lifting heavy vehicles. They are a means to increase your workshop’s productivity and profit with the guarantee of quality and durability.