If you are a car or truck owner, you already know why it’s so important to have the undercarriage of your vehicle routinely checked and maintained. A vehicle’s undercarriage carries all those components that move the vehicle. There’s the wheel assembly along with the transmission, steering rack, and a host of other components giving mobility to the vehicle. If not serviced promptly, any of these components can break down leaving you stranded in the middle of the road.

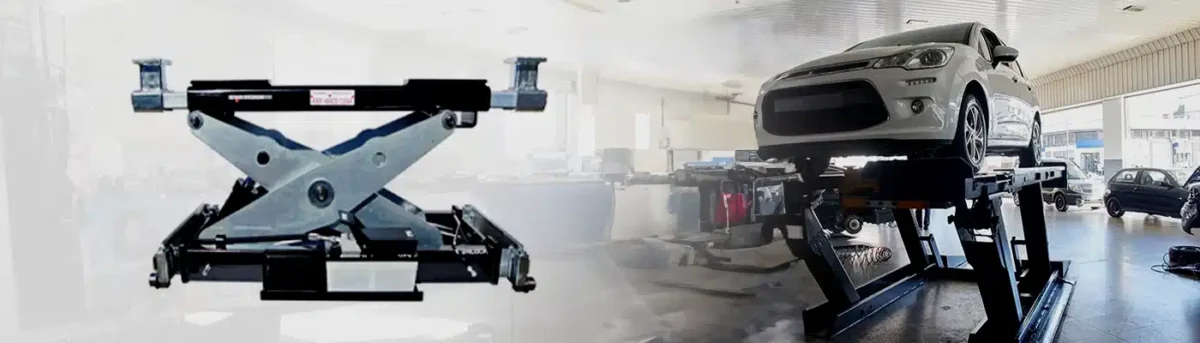

Ask any workshop owner or DIY enthusiast, and they’ll tell you how a heavy-duty truck jack is the most important tool to have in one’s inventory. Cars almost always have scissor jacks as part of their standard toolkits. And there’s not a major workshop in Canada or the US that doesn’t have a heavy-duty pit jack to service truck fleets.

First-time buyers often want to know what to look for in the ideal car or truck jack. If you are a first-time buyer or looking to upgrade your garage equipment and install something robust, this blog is for you. So, what’s the ideal heavy-duty truck jack? Read on!

The Ideal Jack

A heavy-duty hydraulic floor jack for cars and trucks, bridge jack, or pit jack – no matter what you are planning to buy, there are a couple of things you need to look out for.

Lift Capacity

The lift or weight capacity of a jack tells you the maximum load it can withstand before its components give in. It’s important to buy a jack that has a lift capacity exceeding the weight of the heaviest vehicle you are planning to elevate. This ensures the jack’s longevity and saves you precious dollars on repeat purchases and equipment maintenance.

Lift Height

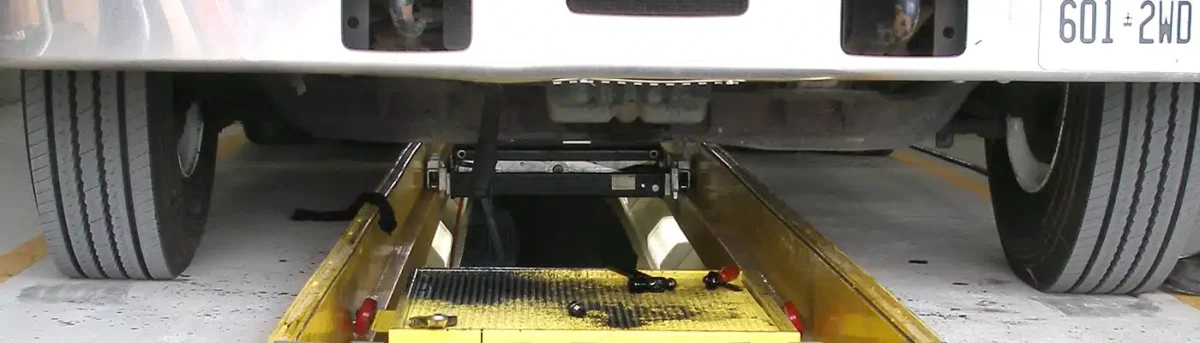

Ground clearance in vehicles tends to vary a lot depending on the vehicle type and modifications made to the suspension setup. Trucks, SUVs, and offroad vehicles have higher ground clearance compared to cars, while military vehicles have beefed-up suspensions to handle harsh terrain.

A jack’s lift height determines how high it can elevate a vehicle for easy access to the undercarriage. If you are planning to work on lifted trucks, offroad vehicles, or military trucks in your workshop, you need a heavy-duty truck jack with a substantial lift height to elevate the vehicle well above its ground clearance.

Robustness

Lifting heavy vehicles day in and day out is no mean feat for a tool. We don’t have to tell you that your vehicle jack needs to be robust. High-grade steel components, lubricated moving parts, forged pistons, and zinc-plated surfaces are some of the things to look out for when buying a new car or truck jack.

Floor jacks and bottle jacks use the principles of hydraulics to lift vehicles. Bridge jacks and pit jacks, on the other hand, use a combination of hydraulics and compressed air pressure for more efficient and smooth lifting. Topline products like Stan Jacks utilize precision-engineered components in their hydraulic and pneumatic mechanisms to achieve precise and safe lifting. These components are robust and durable and will easily last decades under heavy use.

Adaptability

This is particularly important for heavy-duty pit jacks. Because these tools are required to work on different types of vehicles, they must have adapters to suit cars, trucks, EVs, and military vehicles. For instance, pit jacks manufactured by Stan Design come with stackable adapters that match up to any vehicle type you throw at them.

Footprint and Maneuverability

There’s no use having a tool that is difficult to maneuver and occupies too much space in an already crammed-up workplace. In case of jacks, you need a tool with a low collapsed profile for it to slide under a vehicle with low ground clearance. For instance, the Scorpion TJ12S Floor Jack from Stan Design has a collapsed profile of just 8”. Wheels for floor jacks and roller bearings for bridge jacks make them more maneuverable and thus easy to manage.

Safety

Efficiency and safety are equally important when it comes to choosing a heavy-duty truck jack for your garage. Multi-stage locking mechanisms like those used in Stan Jacks make the lifting operation safer for both the operator and the vehicle.

User-friendly Features and Intuitive Controls

User-friendliness is one thing you can’t ignore for any equipment, not least for vehicle jacks. Always prefer heavy duty floor jacks and pit jacks with user-centric features like long handlebars and detachable controls.

User Reviews

Thanks to the Internet, new buyers can easily make informed decisions on which products to buy and which to give a pass. It’s important that you, as a new buyer, look for user reviews on truck jack models and manufacturers before deciding on what to buy.

Summing it up

When you invest your hard-earned money in a tool, you need to ensure that it gives you enough returns to cover buying costs and then some. A heavy duty truck jack is an asset for your garage business. Do not waste money on something that is cheap upfront but has quality issues. Buy a tool that is built to last. Remember, only a reputable manufacturer can ensure such quality.