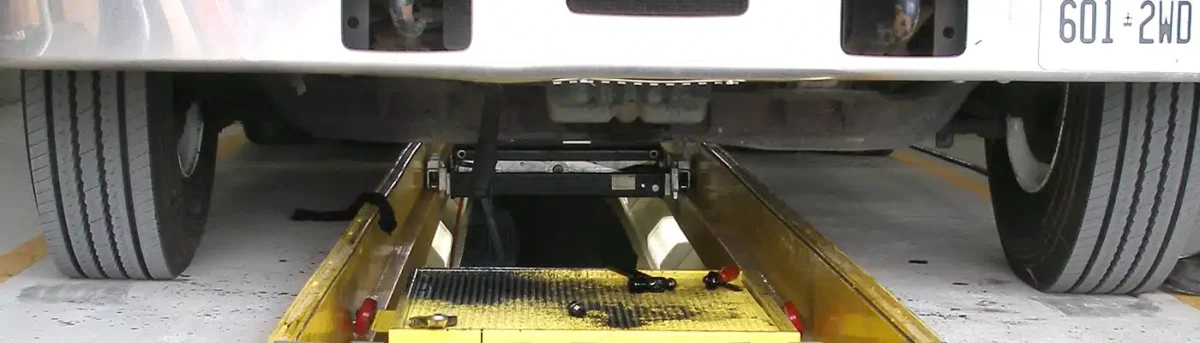

If you’ve ever taken your car for repairs in a commercial automotive garage, you’re likely familiar with vehicle service pits—designated spaces on the workshop floor where vehicles are parked to be serviced from underneath. These are also called vehicle inspection pits or grease pits. They are narrow enough to fit between the wheels of a vehicle yet wide enough for a technician to work within, accessed by stairs or steps. However, their safety can be a concern.

Pit Safety Incidents

Falls into vehicle service pits are common accidents in inspection bays. Poor ventilation in these pits can also lead to fires and explosions from hazardous substances. Traditional fall protection systems, like safety nets, often prove unreliable. Recognizing this gap, Stan Design Inc. has developed innovative solutions.

Stan Design Inc.

Stan Design Inc. is a reputable name in the truck jacking industry in Canada and North America. With over 25 years of experience, they specialize in designing and manufacturing equipment such as floor jacks, pit jacks, rolling jacks, bridge jacks, and fast lube jacks. Their products cater to both personal and commercial needs, offering pneumatic and hydraulic variants to ensure effortless and safe vehicle lifting.

Stan Design Inc. PLC1000 Pit Cover System

The PLC1000 pit cover system is crafted from a proprietary plastic composite material, offering exceptional strength and chemical resistance. This system features 2-foot-long segments that fit the width of your pit. Each lightweight panel weighs only 12 lb. and slides onto one another with ease. Key features include:

- Supports over 1,000 lb. per panel

- Lightweight design at 12 lb. per panel

- Easy sliding and neat stacking

- Chemical-resistant with a traction surface

- Enhances workshop tidiness and professionalism

Stan Design’s Pit Jack Features

Stan Design Inc. offers various pit jacks, including Scorpion pit jacks, bridge jacks (StanJacks), and fast lube jacks. While they vary in load capacities, common features include:

- Multi-level Automatic Safety: Built-in safety locking mechanisms engage automatically at different lifting and lowering heights, eliminating the need for additional jack stands or chocks.

- Detachable Remote Control: Equipped with a detachable remote-control pendant with lift and lower buttons. The dead man switch design ensures full control, providing smooth and fast lifting without hand pumping.

- Reliable and Durable Build: Constructed with high-grade steel and a high-gloss powder coat finish that resists corrosion. Components and accessories are zinc-plated for enhanced appearance and functionality.

- Flexible and Convenient Mobility: Includes low and high adapters stored on the jack, four full-floating casters or wheels with special roller bearings for frictionless rolling, and an extendable pull handle for easy positioning under the vehicle.

- Powerful Operating System: Available in hydraulic and pneumatic variants, utilizing the power of fluids and compressed air for precise performance.

Stan Design’s Pit Jack Models

- Scorpion PJ15: 15,000 lbs. capacity, 34” wide (expandable to 42”)

- Scorpion PJ25: 25,000 lbs. capacity, 34” wide (expandable to 42”)

- Scorpion P12S: 12,000 lbs. capacity, 31” wide (expandable to 46”)

- Scorpion PJ15S: 25,000 lbs. capacity, 31” wide (expandable to 46”)

- Scorpion PJ25S: 25,000 lbs. capacity, 32” wide (expandable to 46”)

StanJack J6000H: 6,000 lbs. capacity, heavy-duty hydraulics, over 11” lifting height

StanJack J7000L: 7,000 lbs. capacity, heavy-duty air bag, over 10.25” lifting height, 7” collapsed height

StanJack J7500H: 7,500 lbs. capacity, heavy-duty hydraulics, over 10.25” lifting height, 7” collapsed height

StanJack J9000H: 9,000 lbs. capacity, heavy-duty hydraulics, over 11” lifting height

StanJack J12000H: 12,000 lbs. capacity, heavy-duty hydraulics

StanJack J15000H: 15,000 lbs. capacity, heavy-duty hydraulics, over 11” lifting height

StanJack J18000H: 18,000 lbs. capacity, heavy-duty hydraulics

StanJack J25000H: 25,000 lbs. capacity, heavy-duty hydraulics

StanJack J35000H: 35,000 lbs. capacity, heavy-duty hydraulics

StanJack J50000H: 50,000 lbs. capacity, heavy-duty hydraulics

They come with heavy-duty hydraulics and a narrow 34.5” top beam.

Pit Jacks J7500HFL

- Capacity – 75,000 lbs.

Pit Jacks J7000LFL

- Capacity – 7,000 lbs.

Pit Jacks J9000HFL

- Capacity –9,000 lbs.