Your car breaks down on the roadside way off the highway with no sign of help within the vicinity. You will at least have to contact the tow truck service, but it will be hours before they can reach you. You have a flat tire. What do you do?

A portable hydraulic jack is what you need in your compartment to get a quick fix. Heavy-duty hydraulic jacks save you the time and effort of waiting for help in situations which can be quickly investigated.

Of course they cannot fix big breakdowns, but for a flat tire, or a quick oil fix (given you stock up on the fluid too), portable hydraulic jacks for trucks come in handy, packing powerful heavy-duty performance.

What are Portable Hydraulic Jacks?

Portable heavy duty truck jacks for trucks work based on the law of fluid mechanics. The law states that when there’s a change in pressure at any point in a confined, incompressible fluid, that change is transmitted throughout the entire fluid without any loss.

Simply put, the law states that if you push or squeeze one part of a fluid, the effect propagates to all other parts of the fluid. To understand the workings of a portable hydraulic jack, let us look at its broad components:

- Hydraulic Oil

- Reservoir or buffer or oil tank,

- Main cylinder or ram,

- Release valve,

- Control valve,

- Check valve,

- Lifting arm or pad,

- Hydraulic pump with piston or plunger, and

- Pump lever or handle.

The reservoir or buffer, or oil tank is the physical compartment of the portable hydraulic jack that holds the hydraulic liquid or pump oil together when it is not in use. The control valve stays in a closed position when the heavy-duty hydraulic jack is not in use to prevent the accidental flow of oil.

The piston is responsible for lifting a heavy load or weight. It is usually mechanically activated by shifting the positions of the handle or pump lever attached to it. This movement builds up pressure in the hydraulic fluid contained inside the reservoir or buffer tank of the heavy-duty hydraulic jacks.

When the handle or lever of the hydraulic pump with piston or plunger is mechanically lowered or raised, it activates force and builds up pressure in the adjoining compartment, i.e., the reservoir or buffer tank containing the hydraulic fluid or pump’s oil, inside portable hydraulic jacks.

The pressure created allows the fluid to move through a check valve into the ram or main cylinder, which then pops out of the main body of the portable hydraulic jack creating the force required to lift the load.

This applied pressure is what transfers the oil from the pump through the check valve and into the main cylinder or the ram, which extends out of the heavy-duty hydraulic jack body. Finally, the release valve relieves the built pressure for easy retraction and lowering of the ram with the load on it, creating the required lifting force and lifting the load.

How Portable heavy duty truck jacks Help You?

In the previous section we explained how a heavy-duty hydraulic jack works. As opposed to pneumatic jacks, since these hydraulic jacks function based on fluid power they can lift heavy loads smoothly in a few seconds to minutes. This is perhaps the biggest way in which heavy-duty hydraulic jacks help you, but we will discuss more values it adds to your life in this section.

- Safety– Heavy-duty hydraulic jacks are best known for the all-encompassing safety that they provide to the personnel handling them. Because of the operating mechanism of hydraulic systems, which by principle require fewer moving parts as compared to their mechanical or electrical counterparts, they are less prone to malfunction. Many jack manufacturers, on top of this, introduce sophisticated safety measures like in-built automatic lock systems which engage at different lifting levels or heights, giving the user more control over the loading process.

- Durability– The unique selling point of hydraulic systems is their capacity to load, lift, suspend, and lower safely heavy and expensive loads. Hydraulic jacks for trucks are durable enough to do just that. Owing to powerful hydraulic cylinders and manufacturer-specific reliability features, they can deliver a smooth ride to customers. For instance, jacks made with high-grade steel body and the finest quality zinc plated components with high gloss powder coat paint accessories allow enhanced functionality that resist corrosion and deterioration.

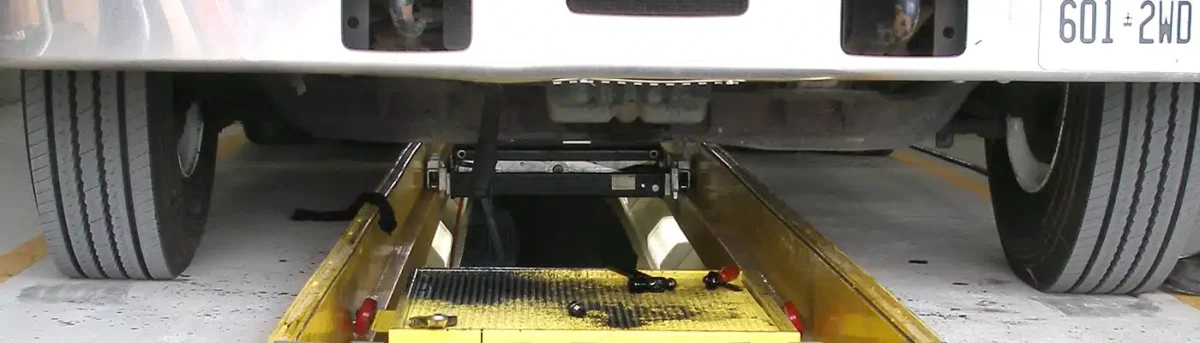

- Portability– Jacks must be portable enough to fit into and be carried around in car compartments for emergency breakdowns. Stan Design Inc. portable hydraulic jacks provide just that value to you. Their compact design- only 7.5”-8.25” collapsed height- enables them to fit virtually any undercarriage of a vehicle with the lowest chassis profile. This small footprint reduces floor space and does not take up much room, allowing for a low-profile high adjustability functionality.

- Adaptability– This brings us to our last point. Portable hydraulic jacks for trucks are highly flexible, making them very convenient for regular use. Each Stan Design Inc. heavy-duty hydraulic jack for trucks comes fitted with special roller bearing wheels that allow for effortless rolling and maneuvering. They also have convenient pull handles that make it easy to position the jack under the vehicle without any hand pumping required. This eliminates the need for additional stands or chocks, although they are adapted to be used with jack stands for other jobs if the requirement arises.

About Stan Design Inc.

Stan Design Inc. is a jack manufacturing and design company that has been in the business for more than 25 years. They produce the highest-quality lifting solutions by fusing the science of manufacturing with the art of creative design. Their portable hydraulic jacks provide a secure way to raise, lower, and suspend your heavy vehicles for upkeep and repairs.

Heavy-duty hydraulic jacks help customers in a variety of industries, including aircraft, automotive, bridges, cable tensioning, house moving, construction, general industrial, laboratory, locomotive, marine, mobile home, railroad, shipbuilding, shoring and stabilizing such as for tunnels and mines, tractors, and trailers.