Truck lifting equipment like hydraulic floor jacks or bridge jacks have been around for centuries now. Traditional jacks have generally been difficult to maintain and operate, due to cumbersome heavy-duty jack operation guidelines and proneness to malfunction.

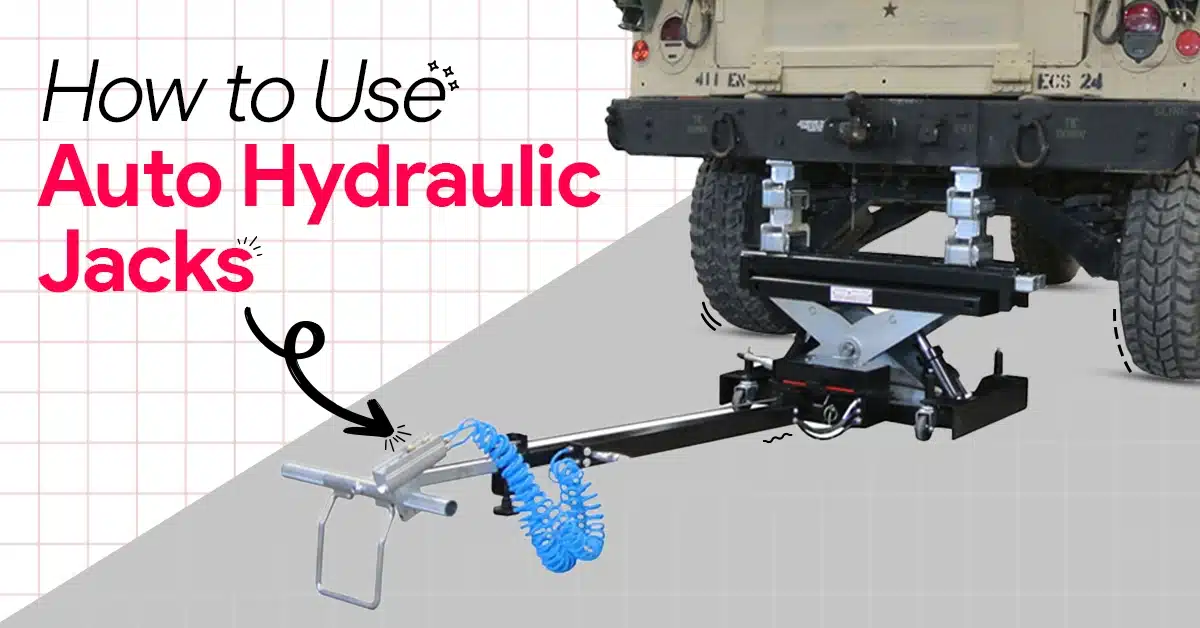

Innovations in safe vehicle lifting practices along with advancements in jack technology have resulted in modern jacks, like Scorpion floor jacks, with features for avoiding jack operation errors.

However, unless you own Stan Design Inc. products like the StanJack or Scorpion lines of jacks, you would need to know some of the common jack operation errors and how to avoid them. In this blog, we discuss just that! Read on.

Common Jack Operation Errors

- Skipping Safety Measures – Your jack requires regular inspection. Safety checks can range from as simple as seeing whether you have cleaned your jack after use and stored it upright in a clean and dry place, to more sophisticated ones like having a checklist to determine its fluid viscosity, etc.

- Not Sticking to Load Capacity – The load capacity of a jack refers to the limit of quantity that it is designed to lift. Overloading a jack is not only detrimental to its durability but also dangerous for the personnel using it, along with the vehicle being lifted.

- Not Removing Obstacles Before Lowering – A most common and easily resolvable issue while operating jacks is not clearing the ground before lowering the vehicle it has hoisted.

- Lifting or Lowering Too Quickly – Another safe vehicle lifting practice involves hoisting and lowering it slowly and steadily, making sure the vehicle remains stable. Remove the jack once the vehicle is fully on the ground. Check that the vehicle is rising evenly and not shifting.

- Not Checking the Surface or Contact Points – Positioning a jack incorrectly below the vehicle, that is, not in the correct jacking point, and lifting vehicles on a slippery or uneven surface is a recipe for disaster.

5 Heavy-duty Jack Operation Guidelines

- Use the Right Jack for the Task – Determine its purpose of use before choosing the type to work with. For instance, a hydraulic floor jack is ideal for home garage work, while a bridge jack is better for heavy-duty lifting.

- Focus on Accurate Positioning – As discussed above, ensure that the lifting point on the load is directly above the center of the jack’s saddle, and it is connected to the jacking point before lifting.

- Avoid Overloading the Jack – Check the maximum weight capacity, or load capacity, of the jack and stick within the permissible limits to avoid overloading the jack and causing accidents.

- Follow Jack Maintenance Tips – Check for any signs of damage or wear and tear and ensure all bolts are tightened securely, along with regular lubrication of the system, handle, base plate, and wheels of the jack.

- Adhere to Proper Jack Usage – Always use proper personal protective equipment (PPE) such as gloves and safety glasses when operating a jack. Follow all safety guidelines provided by the manufacturer of your jack.

Our solutions for safe Vehicle Lifting practices

- Powerful Design – We provide heavy-duty hydraulic and pneumatic variants of our jack models. So, you can choose a gadget based on your requirements, rather than a lack of options. These powerful methods of operations offer a smooth lifting and lowering process, by eliminating the need for exhausting hand pumping.

- Detachable Remote Control – Lift a truck in seconds with full control over the process, using our detachable remote-control pendant. Just push one button on our Scorpion floor jacks, or two dead man buttons- one to lift and one to lower- on our StanJack bridge jacks.

- High-quality Material – Our jacks are built to last with durability, resilience and reliability. We only use the highest-grade materials like fine steel, zinc plated components and accessories, grease fittings, and sustainable finishes like high gloss powder coat paint. This resists oxidation and deterioration, while enhancing their appearance.

- Roller Bearing Wheels – All our jacks have four full floating casters that allow for effortless rolling, extreme ease and maneuvering. The casters are made of special roller bearings that reduce friction and wear, delivering impressive mobility.

- Multi-level Safety – Our in-built automatic three-stage locking mechanism allows us to maintain the car as well as personnel’s safety during the lifting, suspending, and lowering operation. This safety lock mechanism engages automatically at different heights and does not require additional jack stands or chocks for support.

What is Stan Design Inc.?

Stan Design Inc. is a hydraulic floor jacks and bridge jacks designer and manufacturer in Canada. With over two decades of experience in the automotive jack industry, we are at the forefront of making cutting-edge technology accessible for our customers.

At the heart of our innovative features lies a beautiful marriage of the ideal of convenience and safety at affordable prices. Our deep-diving research into analyzing the most pressing issues within the industry revealed that garage owners across the nation were facing the problem of time and money wastage.

They were wasting countless hours every day lifting heavy-duty vehicles with slow and cumbersome hydraulic floor jacks that require multiple stands to support the truck. So, we came up with Scorpion floor jacks with both hydraulic and pneumatic functionality.