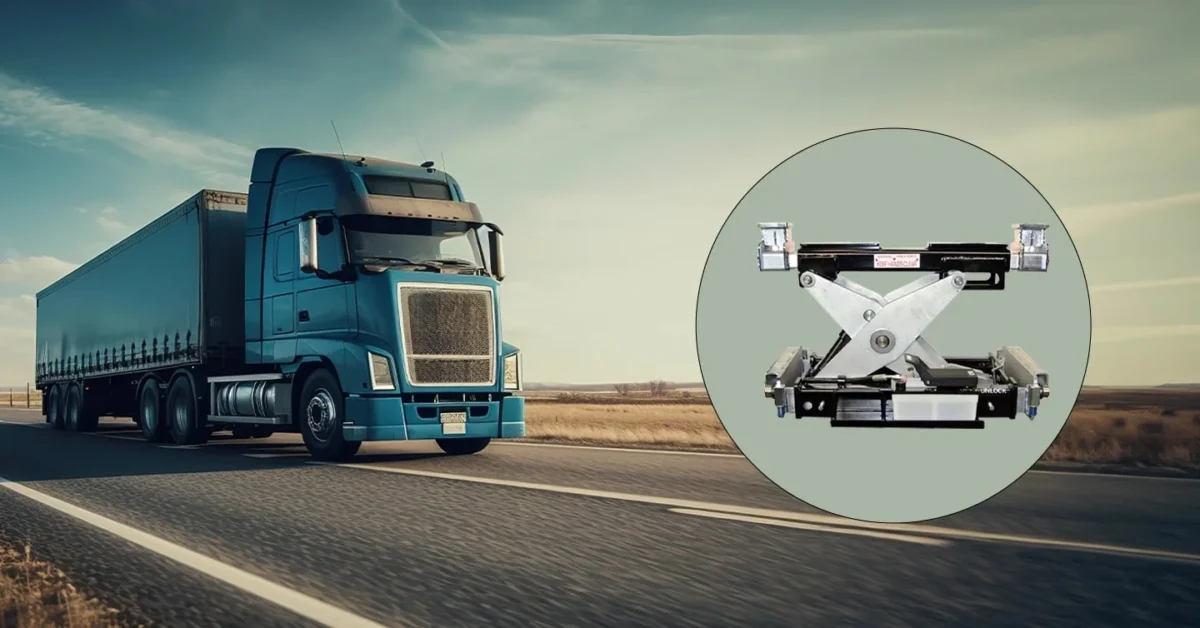

Working in commercial garages or automotive workshops can become a nightmare without the right collection of equipment at your disposal. One such tool in your arsenal is truck jacks. These heavy-duty jacks for trucks are capable enough to make the lifting process of big vehicles smooth and effortless while ensuring safety and stability.

By saving time in lifting heavy loads, suspending them securely to service them efficiently, and lowering them without technical hiccups, truck jacks enable workers to maintain and repair bigger vehicles like heavy-duty military or commercial trucks, buses, sports utility vehicles (SUVs) and all sorts of big automobiles.

Having many different operational mechanisms- mechanical, electrical, hydraulic, hybrid, etc., these jacks deliver high value to professionals wielding them. By lifting and transporting all types of heavy weights, industrial loads, vehicles, and machinery equipment for clamping, jacks aid customers in varying industries, like:

- Aircraft

- Automotive

- Bridges

- Cable tensioning

- House moving

- Construction

- General industrial

- Laboratory

- Locomotive

- Marine

- Mobile home

- Railroad

- Shipbuilding

- Shoring and stabilizing such as for tunnels and mines

- Tractors & trailers

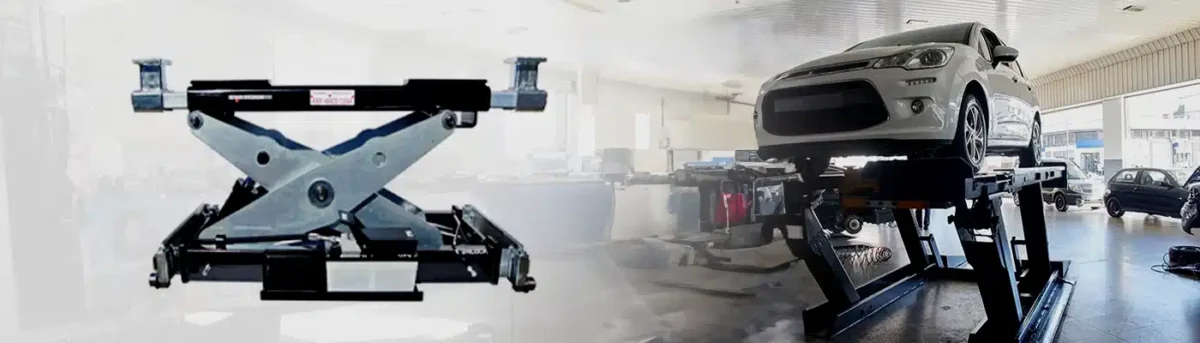

To understand simply the workings of a truck jack like the Stan Design pit jack, let us consider the example of a hydraulic system of operation, consisting of the following broad components:

- Hydraulic oil,

- Reservoir or buffer or oil tank,

- Main cylinder or ram,

- Release valve,

- Control valve,

- Check valve,

- Lifting arm or pad,

- Hydraulic pump with piston or plunger, and

- Pump lever or handle.

The reservoir or buffer or oil tank is the physical compartment of the heavy-duty jack for trucks that holds the hydraulic liquid or pump oil together when it is not in use. The control valve stays in a closed position when the jack is not in use to prevent the accidental flow of oil.

When the handle or lever of the hydraulic pump with piston or plunger is mechanically lowered or raised, it activates force and builds up pressure in the adjoining compartment, i.e., the reservoir or buffer tank containing the hydraulic fluid or pump’s oil.

This applied pressure transfers the oil from the pump through a check valve and into the main cylinder or the ram, which extends out of the hydraulic jack body creating the required lifting force and lifting the load.

What are Factors to Consider for Choosing the Right Truck Jack for Efficient Lifting?

1. Compatibility with Your Vehicle: Before choosing the right jack for lifting heavy vehicles, it is essential to check its specifications to verify its compatibility with your vehicle. This step is important and must not be avoided under any circumstances or considerations because doing so can impose great harm on not only the vehicle being lifted and serviced using the jack, but to the safety and even life of the personnel engaged in the process of lifting and maintaining the vehicle. To ensure compatibility, checking the jack’s weight capacity, size, portability, clearance or lift range, quality, build materials, brand reputation and user testimonials can be a starting point.

2. Weight Capacity: Usually expressed in tonnage, the weight capacity of a jack shows its capability of clamping, lifting, suspending, lowering, transporting, etc. loads of particular weights. The load or weight capacity of a jack is distinctly different from its lift range or size and is not indicative of either. Neither do the jack’s lift range nor its size in any way denote its load capacity. So, if you have a bigger or heavier vehicle to be repaired, going for heavy-duty pit jacks would be a wise choice, while for smaller cars investing in small and more portable repair and maintenance jacks would be sufficient.

3. Size and Portability: The size of a jack directly affects its portability. Heavier jacks, usually made of steel, are more suited for use in commercial garages and automotive workshops where they may be fixed in places for more convenient use. Unlike that, smaller jacks using hydraulic systems to operate either made of lightweight steel or aluminum, can be stored in small storage compartments of cars to be unloaded and used for emergency purposes like fixing a flat tire, etc. However, it is wise to not rely on portability alone while determining the size of the jack being purchased and weigh its compatibility with your owned vehicle or the types of vehicles you commercially service.

4. Clearance: The clearance of a vehicle refers to the distance between the lowest part of its undercarriage (not including the tires) and the ground. Also referred to as ride height or ground clearance, this area is the best suited for car jacks to be implemented for repairs and maintenance. Usually, the higher the clearance, the higher the center of mass of the vehicle. Therefore, this can be translated to suit low lift ranges of car jacks to make it compatible with the clearance of the car being serviced.

5. Brand Reputation and User Testimonials: While making an automotive jack purchase, you should bear in mind its producer and manufacturer. Checking out the brand reputation diligently and doing a fair bit of research on its product description and features, while also reviewing user feedback and testimonials for both the product and producer can go a long way in ensuring that you make a wise investment. For example, our Stan Design pit jacks are highly trusted across the industry as we serve our customers not only before they make a purchase with us, but also long after they sale is closed.

6. Quality and Build Materials: Perhaps, the biggest component in selecting a jack is its safety features. Since it is such a basic consideration, we have not discussed it as a separate point and wish to highlight it through this concluding point about quality and build materials. The quality of a jack should never be compromised based on price points as it can severely constrain the safety of your vehicle and yourself. Checking its build materials, whether steel, aluminum, hybrid, etc. is imperative to determine not only its size and portability but also its quality and sustainability, that is directly proportional to the safety it offers.