Scorpion Pit Jack Jacks are powerful devices used for lifting heavy loads. These potent tools mainly found in workshops and commercial garages are now finding their way into home garages as well as the storage compartments of smaller vehicles. This marked shift comes because of the availability of jack variants with moderations in size and portability.

Be it jacks like the Scorpion pit jack (a specialty line of pit jacks by Stan Design), hydraulic floor jack, or heavy-duty floor jack, all automotive jacks have a single purpose– lifting heavy vehicles for repair and maintenance. Working with great force, good automotive jacks ensure the steady suspension and safe lowering of the hoisted vehicle.

What are Pit Jacks?

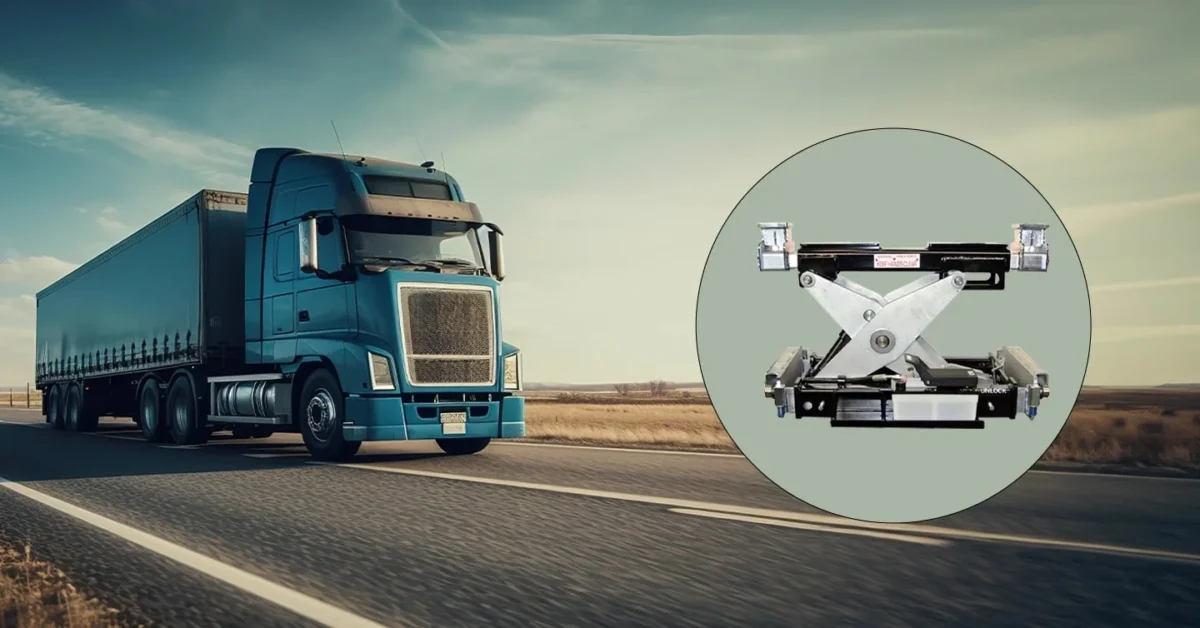

Pit jacks are service jacks that roll down the underground pits below the undercarriage of your vehicle. In essence, they differ from floor jacks by this very feature- that they are designed to work in the service bays or inspection pits that are under the ground level- instead of the above-ground surface right below the clearance of your automobile.

Because of this feature pit jacks are more capable of lifting weights of all sizes and exposing the underside of vehicles for inspection, service, maintenance and repairs. Depending on the size of your service pit, technicians may even climb into them to service the lifted and exposed vehicle undercarriage more efficiently than other jacks could offer.

They are mostly used to service heavy-duty vehicles because of the range of services they can provide. Often considered as the best pit jack for trucks, the Scorpion pit jack from Stan Design is specially designed to fit any pit or ramp application, thanks to their compact and expandable design. It comes with other useful features which we will explore in the later sections.

Stan Design Scorpion Pit Jacks

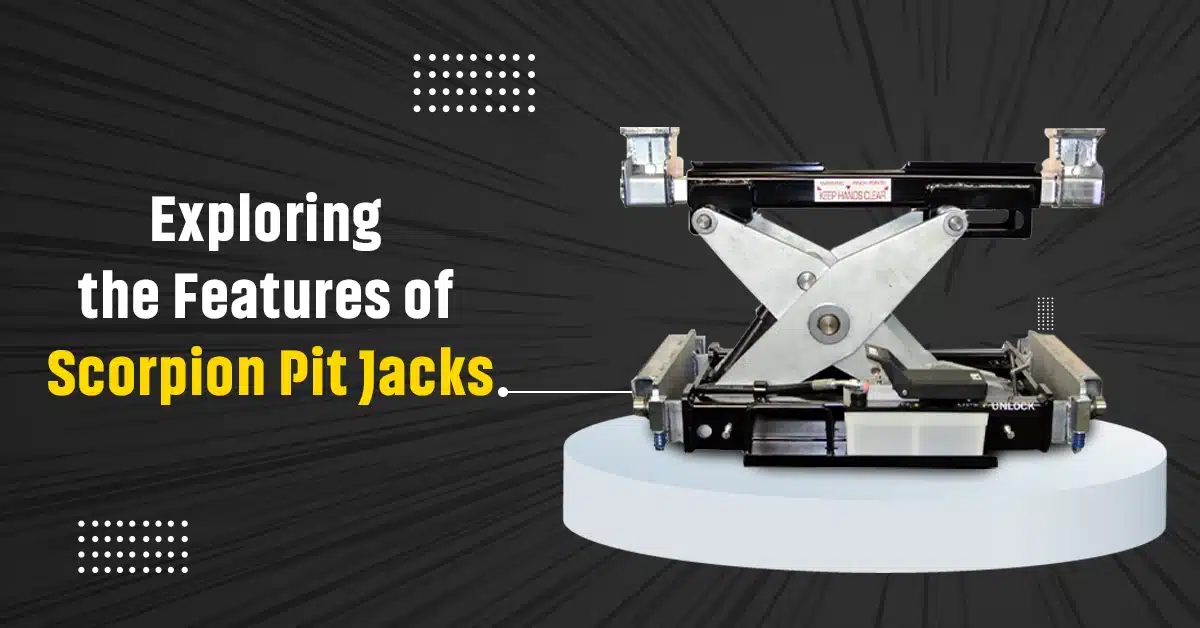

Stan Design’s patented Scorpion Pit Jacks are the result of decades of innovation, engineering, quality and performance making them the most robust workshop pit jack in North America. They are reliable enough to lift the heaviest of vehicles in seconds for service or alignment without risking your safety or wasting your time and money.

They are specially designed to fit any pit or ramp application, thanks to their compact and expandable design. Made with high-grade steel and the finest quality components, they are the most durable jacks on the market. The heavy-duty hydraulics and air motors allow Scorpion pit jacks to surpass all its competitors in performance.

- Versatile: The Scorpion Pit Jack can fit virtually any pit or ramp application due to their compact design only (31”-34” wide) and expandable up to 42”-46” wide.

- Durable: Made with high-grade steel and the finest quality components that resist corrosion, rust, oxidation, and deterioration.

- Powerful: The Scorpion Pit Jack has heavy-duty hydraulics or air motors that offer powerful and smooth lifting without any hand pumping required.

- Safe: The built-in safety locks in the jacks engage automatically at different heights, eliminating the need for additional stands or chocks.

- Flexible: The Scorpion Pit Jack has telescoping arms and stackable adapters that can lift across the axle or on the frame, depending on the vehicle size and shape.

- Easy: Their fitted special roller bearing wheels and pull handles allow for effortless maneuvering and convenient positioning under the vehicle.

- Attractive: The Scorpion Pit Jack has a high gloss powder coat paint and zinc plated components and accessories that enhance their appearance and functionality.

Mechanism of Stan Design Scorpion Pit Jacks

The Scorpion Pit Jack has heavy-duty hydraulics or air motors that offer powerful and smooth lifting without any hand pumping required. Let us learn more about how this hydraulic lifting system works to understand how you may employ the jack for use.

Hydraulic jacks consist of the following broad components- hydraulic oil, reservoir or buffer or oil tank, main cylinder or ram, release valve, control valve, check valve, lifting arm or pad, hydraulic pump with piston or plunger, and a pump lever or handle.

The reservoir or buffer or oil tank is the physical compartment of the heavy-duty jack that holds the hydraulic liquid or pump oil together when it is not in use. The control valve stays in a closed position when the jack is not in use to prevent the accidental flow of oil.

When the handle or lever of the hydraulic pump with piston or plunger is mechanically lowered or raised, it activates force and builds up pressure in the adjoining compartment, i.e., the reservoir or buffer tank containing the hydraulic fluid or pump’s oil.

This applied pressure transfers the oil from the pump through a check valve and into the main cylinder or the ram, which extends out of the hydraulic jack body creating the required lifting force and lifting the load.

How to Choose the Right Stan Design Scorpion Pit Jack?

There is a list of factors to consider while choosing any jack model:

- Weight capacity: While shopping for pit jacks it is imperative to look for the weight capacity (expressed in tonnage) it is designed to lift. The Scorpion jacks are available in variants of 12000- 25000 lb.

- Material: The construction or build of your pit jack, whether it is a steel jack or aluminum jack, is pivotal to assess its performance and sustainability.

- Lift height: It must match the ground clearance of your vehicle. The Scorpion jacks offer an extended range of 20”+.

- Size: The size of your jack impacts its portability. The Scorpion jacks are 31”-34” wide which can be extended up to 42”-46”.

- Safety: Perhaps the most important factor to consider while purchasing a pit jack is its safety features to prevent accidents and mishaps and ensure safe lifting of heavy loads.

- Price: You may be tempted to go after jacks that seem cheap but remember affordability does not always determine quality. Seemingly cost-effective jacks may turn out to be more expensive in the long run.

- Brand reputation: Buying pit jacks from reputable sources, like Stan Design ensures good quality, warranty and customer service.

- User feedback: Products like the Stan Design floor jack or Scorpion pit jack come with authority as they are user tested and rated.

- Compatibility with your vehicle: Not all jacks are suitable for all vehicles. Whether you own a truck or a SUV or other types of cars, it would influence the choice of your pit jack.

Stan Design Scorpion Pit Jack Models:

- Capacity – 15,000 lb

- Dual Hydraulics Arms

- Extended Lifting Height – Over 20”

- Size – 34” Wide

- Expandable Size – 42” Wide

- Capacity – 25,000 lb

- Dual Hydraulics Arms

- Extended Lifting Height – Over 20”

- Size – 34” Wide

- Expandable Size – 42” Wide

- Capacity – 12,000 lb

- Dual Hydraulics Arms

- Extended Lifting Height – Over 20”

- Size – 31” Wide

- Expandable Size – 46” Wide

- Capacity – 25,000 lb

- Dual Hydraulics Arms

- Extended Lifting Height – Over 20”

- Size – 31” Wide

- Expandable Size – 46” Wide

- 20 Ton

- 220v 1 Phase powe

- Dual Locking System, hydraulic & mechanical

- Double acting Telescoping Hydraulic cylinder

- Is a floor running pit jack suitable for inspection Pits & Lube Pits

- Capacity – 25,000 lb

- Dual Hydraulics Arms

- Extended Lifting Height – Over 20”

- Size – 32” Wide

- Expandable Size – 46” Wide

Installed Tire Service – Pit Jack

- TJ14AG – Above Ground

- TJ14SG – Semi-in-Ground

- TJ14IG – In-Ground

- Extended Lifting Height – Over 20”

Coming Soon

PJ20A