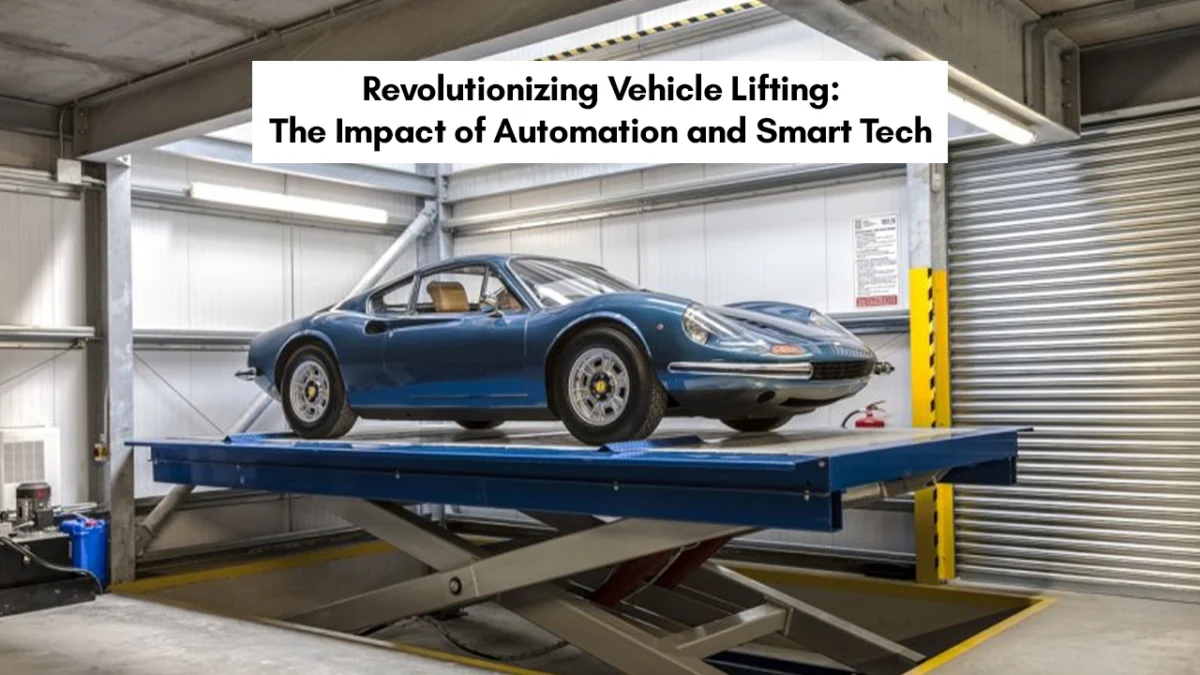

Automated lifting systems represent a significant leap forward in vehicle maintenance technology. These systems utilize advanced sensors, control mechanisms, and smart technologies to perform lifting tasks with minimal human intervention. By automatically adjusting to the specific weight and dimensions of a vehicle, they ensure optimal balance and stability during maintenance procedures. This automation not only enhances operational efficiency but also significantly reduces the likelihood of human error, leading to safer working environments.

Transformation of Automotive Lifting Systems and Integration of Smart Technologies

Modern automotive lifts now incorporate smart features that automate operations and provide real-time data. For instance, systems equipped with sensors can detect misalignments and adjust automatically, reducing human error and preventing accidents. These advancements not only streamline the lifting process but also ensure consistent performance.

To understand the evolution of jacks, from ancient leverage tools to modern hydraulics, sheds light on their pivotal role in various industries like how an automated lifting systems utilize advanced sensors and control mechanisms to perform lifting tasks with minimal human intervention. These systems can automatically adjust to the specific weight and dimensions of a vehicle, ensuring optimal balance and stability during maintenance procedures. This automation enhances operational efficiency and significantly reduces the likelihood of human error, leading to safer working environments.

For instance, Stan Design’s Scorpion Floor Jacks incorporate advanced features that streamline the lifting process, providing technicians with reliable and user-friendly equipment.

In this modern time of vehicle maintenance, the shift from manual jacks to advanced lifting systems marks a significant leap in efficiency and safety. Traditional methods required considerable physical effort and posed various risks. Today, the integration of automation and smart technologies has revolutionized these systems, offering precision, ease of use, and enhanced safety features.

The Role of Smart Technology in Lifting Systems

Integrating smart technologies into lifting systems brings features such as real-time diagnostics and predictive maintenance. Sensors embedded within the equipment can monitor usage patterns and wear, alerting operators to potential issues before they escalate. This proactive approach minimizes downtime and extends the lifespan of the equipment, contributing to more streamlined workshop operations.

Stan Design’s Bridge Jacks exemplify this integration, offering precise control and monitoring capabilities that enhance both efficiency and safety in vehicle maintenance tasks.

Enhancing Efficiency through Automation

Automated lifting systems significantly reduce the time and effort required for vehicle maintenance. Benefits of Investing in North American Made Truck Jacks, is technicians can operate lifts with minimal manual intervention, allowing for quicker turnaround times. Features like programmable lift heights and synchronized movements enable precise positioning, facilitating tasks such as wheel alignments and undercarriage inspections.

The Optimus 3in1 Fast Lube system by Stan Design is a prime example of how automation can streamline multiple maintenance processes, combining efficiency with versatility.

Safety Improvements with Smart Lifting Solutions

Safety is paramount in any workshop environment. Automated lifts come with built-in safety mechanisms, such as automatic load-limiting systems that prevent overloading and emergency stop functions that halt operations instantly when necessary. These features protect both the vehicle and the technician, reducing the likelihood of workplace injuries.

For example, Stan Design’s Scorpion Pit Jacks are designed with safety features that ensure stable and secure lifting, providing peace of mind during complex maintenance tasks.

Key Factors to Consider When Selecting a Vehicle Jack

When selecting a vehicle jack, it’s essential to assess factors such as lift capacity, lift height, robustness, adaptability, footprint and maneuverability, safety features, and user-friendly aspects. For a comprehensive guide on these considerations, refer to Stan Design’s guide how a heavy-duty truck jack is the most important tool to have in one’s inventory

Real-World Applications and Case Studies

Leading automotive workshops have adopted smart lifting technologies to great effect. For instance, the implementation of smart hydraulic jacks has enabled technicians to lift vehicles more quickly and safely, reducing service times and increasing customer satisfaction. These real-world applications underscore the tangible benefits that automation and smart technologies bring to the automotive maintenance sector.

Stan Design’s sponsorship of the ATPA Championship Pull highlights their commitment to advancing lifting technology in real-world scenarios, demonstrating the effectiveness of their innovative equipment in demanding environments.

Challenges and Considerations – Future of Automotive Lifting Systems

Despite the clear advantages, integrating automation into existing workshop infrastructures presents challenges. The initial investment can be substantial, and staff may require training to operate new systems effectively. However, these challenges are often offset by the long-term gains in efficiency and safety, making the transition a worthwhile consideration for forward-thinking workshops.

Stan Design offers comprehensive support and training for their products, ensuring that workshops can seamlessly integrate advanced lifting systems into their operations.

As technology continues to evolve, we can anticipate further innovations in automotive lifting. Future systems may incorporate artificial intelligence to enhance decision-making processes or utilize the Internet of Things (IoT) to enable seamless communication between equipment and technicians. These advancements promise to further elevate the standards of efficiency and safety in vehicle maintenance.

Stan Design remains at the forefront of these developments, continually researching and implementing cutting-edge technologies to meet the evolving needs of the automotive industry.