The North American economy is heavily dependent on the trucking industry. Every day, hundreds of thousands of trucks carry essential commodities from one part of the continent to another. But what keeps the truck fleets up and running? You guessed it right – the numerous workshops dotting the continent! And what do these workshops rely on to service fleets? Pit Jacks.

There are all kinds of heavy-duty truck jacks available on the market. But pit jacks rule the roost when it comes to servicing trucks and other heavy vehicles. No other variety of truck jacks comes close to pit jacks in terms of efficiency, safety, and speed. That says something about these cool tools, doesn’t it?

Workshops across Canada and the US rely on pit jacks to safely lift loaded trucks, buses, and all kinds of heavy vehicles for undercarriage repairs and maintenance. Reliability, intuitive design, and robust construction make pit jacks extremely desirable among workshop owners and DIY enthusiasts worldwide.

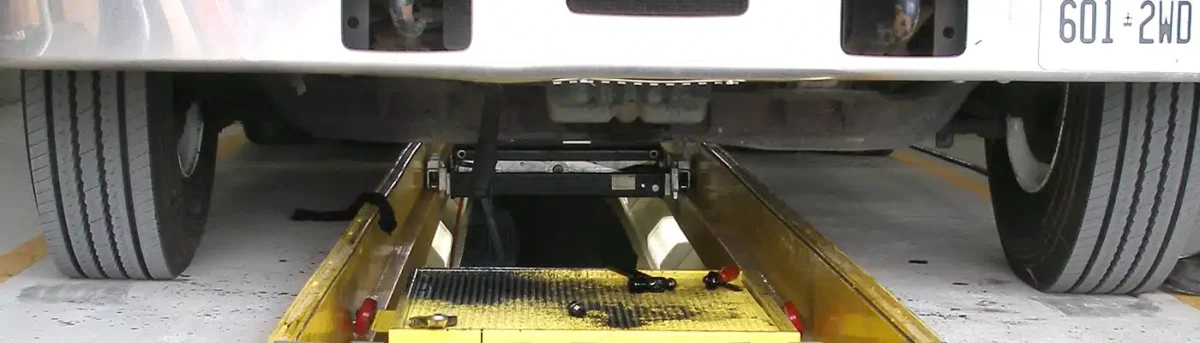

Here’s a look at how a pit jack functions:

First things first: to own and operate a pit jack, you need a dedicated service pit in your workshop. Once the jack has been installed, the operator can maneuver it into position beneath the vehicle using a set of roller bearings. A hydraulic system aided by compressed air causes the lifting arms to elevate a vehicle. Well-lubricated components ensure that the lifting operation goes smoothly and efficiently every time, keeping the operator and the vehicle safe.

In case you didn’t know, we use the same hydraulic power and compressed air combination in our Scorpion Pit Jacks to make lifting loaded trucks look as easy as a walk in the park. Our products are designed for controlled, multi-stage elevation, allowing technicians to perform repair jobs without having to worry about safety.

What are the qualities to look for in a pit jack?

- Sturdiness is Key: Your pit jack needs to be tough. It’s going to be lifting trucks and other heavy vehicles, after all. Always go for a heavy-duty truck jack made from robust materials like high-tensile steel. A corrosion-proof coat is a must for the wet season and moist climates.

- Hydraulic Power: Think of the hydraulic system as the muscles of a heavy-duty truck jack. It does all the heavy lifting to reduce downtime and ready vehicles in no time. Hence, it’s prudent to choose a truck jack with a reliable and smooth hydraulic system. We equip our Scorpion Floor Jacks and Pit Jacks with a pneumatic or compressed air system to make things easier for the built-in hydraulic system and give you peace of mind.

- Weight Capacity Matters: Trucks are big and bulky vehicles hauling around tons of weight. Lifting them requires considerable effort on the part of the equipment. Make sure your truck jack can handle the weight of the vehicles you plan to work on.

- Versatility is the key: Service pits can vary in width. A good pit jack has an expandable design to adapt to pits with varying dimensions. This means it can easily fit under all sorts of vehicles and function in any pit nationwide. This versatility is crucial, especially when dealing with loaded or lifted trucks.

- Maneuverability: Your pit jack must be highly maneuverable and easy to operate. Go for one with smooth roller bearings for easy maneuverability. This makes positioning the lifting arms under the truck a breeze, saving you time and energy.

- Safety Features Are Non-Negotiable: Safety is paramount when dealing with heavy machinery. Ensure your pit jack comes with safety features like a reliable, multi-stage locking mechanism to keep the truck from wobbling when lifted.

- Budget-Friendly without Compromise: While it’s tempting to go for the cheapest pit jack on the market, remember that cheap isn’t always good. Find a piece of equipment that fits your budget without compromising on quality.

Why Choose Scorpion Pit Jacks?

We at Stan Design take pride in our ability to produce class-leading vehicle lifting solutions that prove to be prized possessions for workshop owners all across Canada and North America. The Scorpion Pit Jacks from our stable have been serving the truck servicing industry for quite a while now.

Here’s why you should choose the Scorpion Pit Jack for your workshop:

- Our pit jacks and floor jacks are the result of years of innovation and testing. We believe in delivering the absolute best for our clients.

- The Scorpion Pit Jacks can fit into any service pit, making them versatile and desirable for workshops big and small.

- We use high-grade, corrosion-resistant steel and other high-quality materials to manufacture our heavy duty truck jacks because we value your safety more than anything else.

- Forget long downtimes! Heavy-duty hydraulics boosted by compressed air motors make lifting operations for the Scorpion Pit Jacks smooth, efficient, and quick.

- Throw any truck at it and the Scorpion Pit Jack will come out with flying colors! The jack’s telescoping arms and stackable adapters fit all vehicle types.

- Precision-engineered roller bearings make the Scorpion Pit Jack a breeze to operate with ultra-smooth maneuverability.

- And our products look good in your workshop with a glossy finish and powder-coated components!

Endnote:

No matter which pit jack you buy, always focus on quality and durability. Like we said earlier, what’s cheap upfront might prove to be expensive in the long run.

Happy lifting!