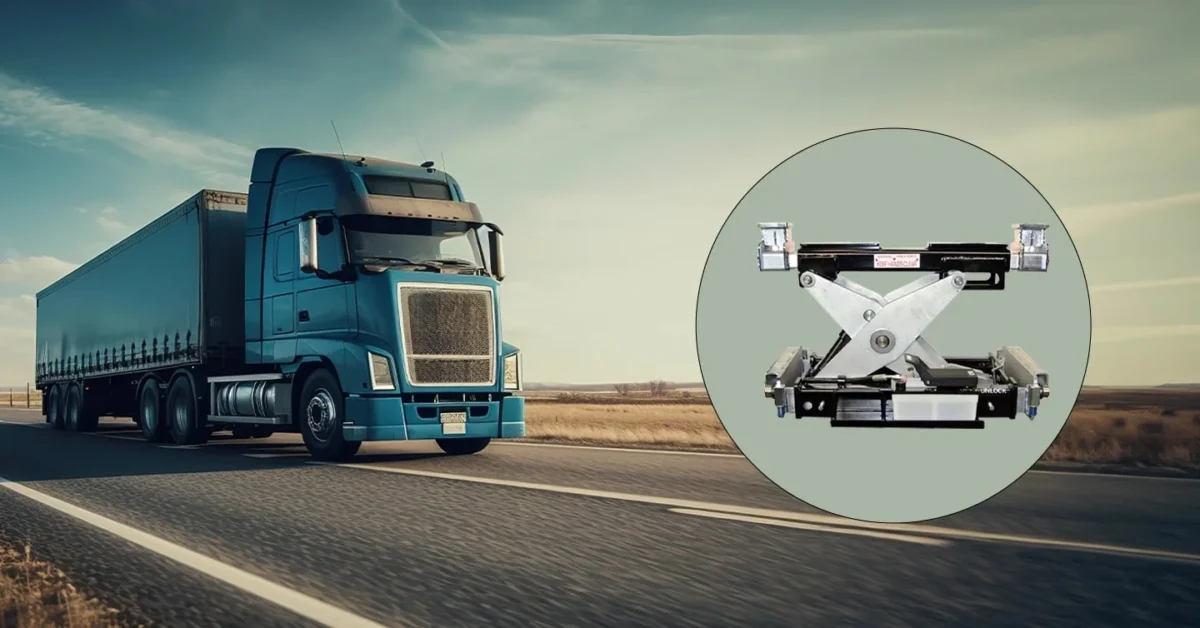

Auto floor jacks are tools or devices that are a must for commercial, military, as well as modern personal garages. As they come in handy for quick inspections of automobiles and their parts, their uses and benefits cannot be overstated.

Used mainly for the purpose of lifting, suspending, and lowering heavy loads like vehicles (even of the military grade) for service, repairs, and maintenance, auto floor jacks are a convenient and safe solution for workshop mechanics and professionals as well as individual do it yourself (DIY) enthusiasts.

These jacks have applications in a wide range of industries, apart from the automotive market, some of which are- aircraft, bridges, cable tensioning, house moving and mobile homes, construction, general industrial, laboratory, locomotive, marine, railroad, shipbuilding, shoring and stabilizing, tractors and trailers.

Auto Floor Jack- Mechanism of Operation

Auto floor jacks can operate using a variety of mechanisms, meaning that their parts can be made to work using various principles of scientific engineering and technology, like mechanical, electrical, hydraulic, air bags or air motors, hybrid, etc.

Of them, the hydraulic system of working, based on Pascal’s law (also known as Pascal’s principle, or the principle of transmission of fluid-pressure), is the most commonly used. From helping lift heavy duty military grade trucks to smaller and lighter family cars, hydraulic floor jacks come into use for any maintenance purpose.

To understand the benefits of hydraulic auto floor jacks, let us understand how hydraulics in jacks work. Where conventional floor jacks wear out easily, these jacks lift high and heavy with ease, safety and speed.

What are Hydraulic Floor Jacks?

Its components work in accordance with Pascal’s law to produce applications in a range of fields beyond the automotive industry, as discussed above. But for the sake of this blog, we will only explore its mechanism in lifting heavy trucks and buses off the ground for repairs and maintenance.

Hydraulic floor jacks are mechanical devices used to lift heavy loads and forces like trucks, sports utility vehicles, or other types of cars, among other heavyweight items.

The anatomy of any hydraulic floor jack can be broken down into these main parts, namely:

- Reservoir or buffer tank

- Pump with piston or plunger

- Pump lever or handle

- Check valve

- Main cylinder or ram

- Release valve

- Handle

The reservoir or buffer tank is the physical compartment of the floor jack which holds the hydraulic fluid or pump oil. When the handle or lever of the pump with piston or plunger is mechanically lowered or raised, it builds up pressure in the adjoining compartment, i.e., the reservoir or buffer tank containing the hydraulic fluid or pump’s oil.

This applied pressure is transferred from the pump through a check valve and into the main cylinder or the ram, which extends out of the hydraulic floor jack body creating the required lifting force and lifting the load.

How to Choose Hydraulic Floor Jacks?

While choosing hydraulic floor jacks, there are just a few specifications that you need to keep in mind.

Check the features like build or material- whether heavy like steel or portable like aluminum- size and weight or load capacity, lift range, price and quality, safety offerings like locking mechanisms, and finally the brand reputation and user reviews of the product and client testimonials of the business or brand.

Benefits of Using Auto Floor Jacks in 2024

Size, Weight and Portability– Most floor jacks are designed to occupy less space, and are therefore lighter than other jacks, making them portable enough to be carried around.

Hydraulic Power Does Not Jam– Since these jacks use hydraulic power to work, they are less likely to jam due to rust in the screw thread as unlike mechanical jacks which work by using them.

Weight Capacity– As hydraulics generate greater lifting force, these floor jacks can lift heavier loads compared to other jacks.

Lift Range– This increased lifting force allows them to lift loads to greater heights, giving them a higher lift range.

Simple to Use– It is easier to use as its working mechanism is simple, making it a convenient choice for a range of clientele, especially do it yourself-ers (DIY-ers). Some can even lift heavy-duty trucks in seconds with the push of just one button.

Effective with Heavy Loads– Loads are lifted with minimum effort as hydraulic mechanisms make it easier to lift heavy and high using fluid mechanics.

Durability and Reliability– Because of hydraulic jacks’ fewer moving parts, and high-quality and the finest grade build materials like steel, it can stand the corrosion, rust, oxidation, deterioration, and wear and tear of lifting for decades to come.

Low Profile– These jacks have an extended and elevated reach while offering sustained and stable lift and minimal upkeep needs.

Safety– The built-in three-stage safety locks in some auto floor jacks engage automatically at different heights, lifting the entire front or rear of your vehicles without any danger, eliminating the need for additional stands or chocks.

Maneuverability– Some auto jacks come with four full floating casters that guarantee ease and impressive mobility, while making them highly adjustable.

Versatility and Flexibility– Some hydraulic floor jacks fit virtually any pit or ramp application due to their compact design (only 7.5-8.25” collapsed height).

Attractiveness– Most of these floor jacks have a high gloss powder coat paint and zinc plated components and accessories that enhance their appearance and functionality.

5 Best Floor Jacks for Sale that Use Hydraulic Mechanism of Operation

- Capacity- 24,000 lbs./12 Tons

- Only 8’’ Collapsed Height

- Lifts Over 15.75”

- Capacity- 24,000 lbs./12 Tons

- Only 7.5’’ Collapsed Height

- Lifts Over 15”

- Capacity- 28,000 lbs./14 Tons

- Only 8.25” Collapsed Height

- Lifts Over 20”

- Capacity- 24,000 lbs./12 Tons

- Only 8’’ Collapsed Height

- Lifts Over 15.75”

- Capacity- 25,000 lbs./12.5 Tons

- Lifts Over 36”

Extendable Beam with Stackable Adapters Designed for All Military Vehicle Applications